In the previous article, we introduced how one type of pumping technology—positive displacement (PD) solid-body plastic air-operated double-diaphragm (AODD) pumps—possesses the design and construction features that are necessary to guarantee full containment of dangerous chemicals, while also offering working characteristics that enable the highest level of operational efficiency to be achieved. While safety in handling these chemicals is a top concern for those who come in contact with them, there is also a secondary one: these chemicals are often very expensive and any loss due to leakage or release has a direct effect on the manufacturer’s bottom line. In this concluding piece, we will offer a list of features and benefits for handlers of dangerous chemicals need to look for when selecting an AODD pump, as well as compatibility and volumetric consistency concerns presented by some types of pumps during operation.

THE SOLUTION

While other PD-pump technologies have shortcomings when handling dangerous chemicals, the AODD pump does not come with such concerns. Specifically, plastic solid-body AODD pumps are the preferred choice over their injection-molded cousins. In general, solid-body AODD pumps are stronger and have a longer life cycle with less required maintenance. Injection-molded plastic pumps, on the other hand, can have small cavities or crevices in the body where liquids can accumulate and potential leak paths can be created. During their operation, injection-molded pumps can also bounce more than solid-body models, which can loosen pipework and increase the chances for a product leak.

Plastic AODD pumps can also be constructed of materials that are specifically compatible with the chemicals that are being handled, which eliminates corrosion and leak concerns. The overall design and operation of AODD pumps gives them dry-run capability and good controllability, while they are seal-less. Their compressible drive medium permits gentle delivery with attenuated pressure peaks. Start-up is simple and the space required is considerably less than in the case of piston-actuated diaphragm pumps or eccentric screw pumps.

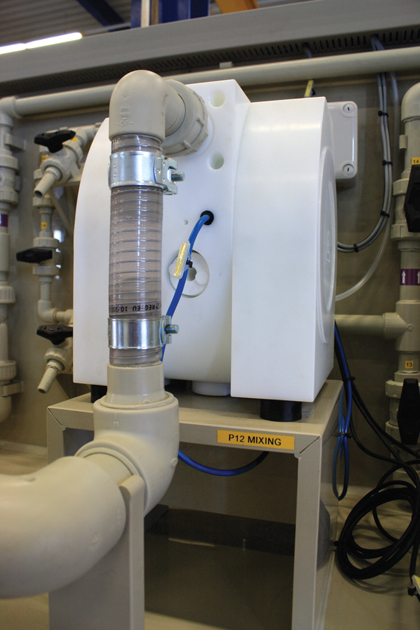

Feature Image: Harsh chemicals can cause compatibility concerns when used with some types of pumps. Almatec® E-Series AODD Pumps can be constructed of plastic materials that are specifically compatible with the chemicals that are being handled, which eliminates corrosion and leak fears.

Above: Other positive displacement pump styles like gear and lobe will lose volumetric consistency over time, leading to higher operating costs. By the nature of their operation, Almatec® E-Series AODD Pumps reliably maintain their flow rates over time, resulting in optimized production cycles and energy usage.

E-SERIES AODD PUMPS

Almatec® Maschinenbau GmbH, Kamp-Lintfort, Germany, is a premium manufacturer and the actual inventor of plastic solid-body AODD pumps and offers an extensive product range. In the handling and transfer of dangerous chemicals, Almatec, which is a product brand of PSG®, a Dover Company, recommends its E-Series AODD Pumps. E-Series pumps offer a long list of features and benefits for handlers of dangerous chemicals:

- Solid-Body Construction. E-Series pumps are CNC-machined from solid blocks of polyethylene (PE) or polytetrafluoroethylene (PTFE). The result is a pump that is not prone to the creation of leak paths while being able to operate with the most dangerous chemicals in the harshest pumping environments.

- Diaphragm and Containment Ring. The E-Series features a unique stainless-steel containment ring and ring-tightening structure that helps create consistent high-torque compression that pulls the components tightly together and compresses the diaphragm in such a way that a leak-free seal is achieved.

- PERSWING P® Air Control System. The PERSWING P® is a lube-free valve with only two moving parts that allows the E-Series pump to achieve superior flow-rate efficiency and air consumption, which helps lower the overall cost of operation.

- Material Compatibility. The E-Series pump’s housing can be constructed of PE, PTFE, PE conductive or PTFE conductive, which allows it to be used with a wide range of chemical formulations. Additional versatility in regards to material compatibility is realized through the availability of EPDM, PTFE/EPDM and NBR diaphragms; EPDM, PTFE, NBR and stainless-steel ball valves; and PTFE cylinder valves.

- Intrinsic Safety. E-Series pumps that are constructed of PE/PTFE conductive plastics are intrinsically safe and meet the requirements of the ATEX 94/9/EG directive. This means they can be safely used in explosive atmospheres or when pumping flammable liquids.

During their operation, injection-molded AODD Pumps can bounce, which can loosen pipework and increase the chances of a chemical leak. Almatec® solid-body AODD Pumps are more stable during their operation, which leads to a higher level of product containment.

Almatec is now offering its E-Series AODD pumps, which can be used a s a direct replacement for its previous A-Series line, in seven sizes: the ¼ inch (6.4 millimeter) E08 with flow rate to 4 gallons (15 liters) per minute; the 3/8 inch (9.5 millimeter) E10 with flow rate to 6 gallons (23 liters) per minute; the ½ inch (12.7 millimeter) E15 with flow rate to 15 gallons (55 liters) per minute; the 1 inch (25.4 millimeter) E25 with flow rate to 35 gallons (130 liters) per minute; the 1-½ inch (38.1 millimeter) E40 with flow rate to 88 gallons (330 liters) per minute; the 2 inch (50.8 millimeter) E50 with flow rate to 160 gallons (600 liters) per minute; and the 3 inch (76.2 millimeter) E80 with flow rate to 210 gallons (800 liters) per minute.

CONCLUSION

You may not want to see how they are made, but we can’t live without laws. The same is true for thousands of consumer or industrial products that are manufactured on a daily basis. While we may not want to know what types of dangerous chemicals, solvents, caustics or acids are being used to make paints, detergents, paper and fertilizer, we also know that we can’t live without them and that we don’t want them to be released to the atmosphere or environment.

That’s why full containment of these hazardous, flammable or explosive substances is a front-of-mind concern for the plant operators who handle them. Those concerns can be alleviated, however, through the use of pumping equipment that has been designed to achieve full containment of dangerous chemicals. While other pump technologies can claim to do this, only plastic solid-body AODD pumps, specifically the E-Series model from Almatec, can turn those claims into reality. ◆

Peter Schüten is the Almatec® product manager with Almatec® Maschinenbau GmbH, Kamp-Lintfort, Germany. He can be reached at peter.schuten@psgdover.com or +49.2842.961.0. Almatec is one of the world’s leading manufacturers of air-operated double-diaphragm (AODD) pumps, owns numerous patents and has one of the largest product ranges in the field of pneumatic diaphragm pumps. Almatec is part of PSG®, a Dover company. PSG is comprised of several of the world’s leading pump brands, including Abaque®, Almatec®, Blackmer®, Ebsray®, Griswold™, Neptune™, Maag Industrial Pumps, Mouvex®, Quattroflow™, RedScrew™ and Wilden®. You can find more information on Almatec and PSG at www.almatec.de and www.psgdover.com.

____________________________________________

MODERN PUMPING TODAY, August 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()