Chukar Waterjet’s subsea waterjet system is bringing the power of ultra-high pressure (UHP) waterjet technology to the deepwater subsea environment, while also improving the safety and effectiveness of subsea operations. With operating at depths up to 10,000 feet (3000 meters) for underwater cutting and blasting operations, Chukar Waterjet’s subsea systems are leading engineers to rethink what’s possible in some of the world’s most dangerous yet fragile ecosystems.

The UHP waterjet system was used to blast away hydrates that were clogging a containment system 5000 feet (1500 meters) underwater. After the hydrates were removed, the cap was successfully installed, helping to stop the oil spill.

CLEANING UP A TRAGEDY

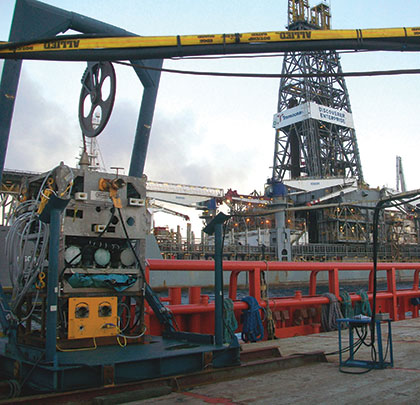

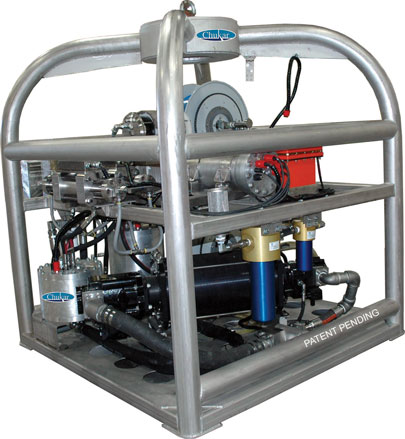

Chukar Waterjet played a key role in helping to stop the 2010 Gulf of Mexico oil spill by providing ultra-high pressure waterjet equipment and application expertise to blast away hydrate ice crystals that had formed inside a containment cap at the Macondo well spill site, clogging the containment system. Chukar Waterjet and sister company Jet Edge, Inc. custom engineered a 36,000 psi (2500 bar) waterjet intensifier pump that was dropped 5000 feet (1500 meters) into the Gulf to power a robot-operated waterjetting lance that blasted away the hydrates.

To ensure the hydrate remediation project’s success, the companies utilized advanced filtration and ultra-high pressure seal technology capable of withstanding the harsh undersea environment. The system was designed to blast with sea water or liquid gas. As a result, Chukar Waterjet developed the first-known waterjet system capable of operating in water depths in excess of 5000 feet (1500 meters), opening a new frontier for waterjet technology.

Chukar provided onsite applications engineering services throughout the project, working with a subsea technology company, an offshore logistics and supply company, an offshore transportation company, BP, and an independent safety group to ensure successful completion of the project.

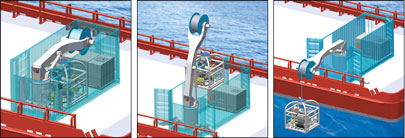

These graphics demonstrate how Chukar Waterjet’s deepwater subsea waterjet skid might be stowed, launched, and deployed from a vessel.

FOR CLEANUP AND FOR CUTTING

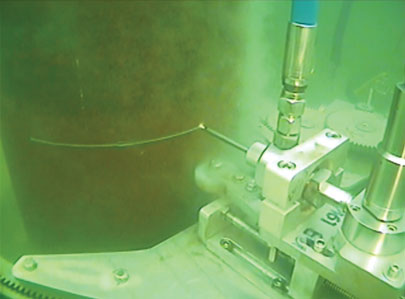

In April 2013 Chukar Waterjet performed a successful test cut in Lake Superior in Thunder Bay, Ontario, Canada. Chukar used an underwater ultra-high pressure waterjet pipe cutter to cut a 14 inch (356 millimeter) diameter ½ inch (12 millimeter) thick steel pipe. The cut was completed in fewer than twenty minutes.

Unlike conventional tools, waterjet systems cut without heat, reducing the hazard of igniting trapped pockets of gas during cutting. Waterjet system tools cannot bind in the cut, jeopardizing asset integrity.Chukar’s subsea waterjet technology improves the safety and effectiveness of subsea operations, allowing operators to access new types of work and larger projects. Chukar’s subsea waterjet system can be operated by a diver or ROV, and its remote-controlled operational capabilities make it suitable for projects requiring diverless operations.

SHARING THE SUCCESS, PUSHING THE ENVELOPE

Since the Gulf accident, the company has developed subsea waterjet equipment operable to 10,000 feet (3000 meters). Chukar systems can also cut steel up to 9.8 inches (250 millimeter) thick and quickly blast away concrete weight coatings, corrosion and marine growth at pressures up to 55,114 psi (3800 bar). Chukar Waterjet also supplies high quality waterjet parts for waterjet cutting and cleaning equipment, offering a complete line of waterjet replacement parts for all major brands.

So far, Chukar Waterjet is the only waterjet manufacturer in the world that offers ultra-high pressure (UHP) waterjet equipment capable of operating in the deepwater subsea environment. The company plans on exhibiting its systems during the fall at a variety of trade shows and industry events, including Offshore Europe, Oceans 13, and OTC Brasil, to further explore the boundaries of waterjet technology.

This photo was captured from the waterjet skid’s onboard video camera during the Lake Superior test.

NEW HORIZONS AWAIT

Chukar’s deepwater subsea waterjet system has numerous applications for deepwater emergency response operations, salvage operations, and rapid de-mobilization operations.

In the coming years, Chukar expects more applications to become available to this technology as word spreads of not only waterjetting’s power but also its safety and reliability when compared to traditional methods of cutting or cleanup. Unfortunately, as exploration expands into deeper and deeper water, so too do the accidents and oil spills associated with them. Although everyone hopes tragedies like the Gulf oil spill can be avoided, it would be unwise not to invest in the necessary technologies their cleanup’s demand.■

_________________________________________________________________________

ABOUT THE AUTHORS

Warren Christopherson is the operations manager and Nancy Lauseng is the marketing manager for Chukar Waterjet, Inc. For more information, visit www.chukarwaterjet.com, or call 888.497.8749 or 763.497.8730 or email subsea@chukarwaterjet.com.

_________________________________________________________________________

MODERN PUMPING TODAY, August 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()