As process automation advances, so too does the need for guidance on how to apply each technology effectively. In part 1 of this article, we discussed distributed control systems (DCSs) and programmable logic controllers (PLCs)—both their histories and their differences. In this section, we’ll examine some of the key considerations when choosing a control system platform and some of the more common application guidelines.

[h2]THE RISE OF HYBRID CONTROL SYSTEMS[/h2]

Given the complexity of today’s control applications, the choice of controller technology isn’t limited to DCS or PLC. On the contrary, advances in process automation and controller technology make it possible for PLC and DCS to coexist in a networked environment—in hybrid control systems.

Hybrid controller integration offers plants more options to cost effectively optimize existing systems, whether the goal is to add capabilities, streamline processes, increase capacity, or improve operational efficiency. Consider the following application criteria:

[h3]Speed[/h3]

Controller speed is vital to safety and quality, particularly in processes involving interlocking and motion control, where controllers operate at millisecond speeds. PLCs historically perform more cost-effectively than their DCS counterparts when it comes to processing high-speed discrete data such as in assembly lines and equipment sequencing. However, DCSs have been more cost effective at crunching analog signals in more complex operations involving more than single-loop control strategies. One typically selects a PLC to allow flexibility and different methods of performing similar operations. DCSs are configured to trade customization for repeatable and dependable performance.

[h3]Criticality[/h3]

Risk relative to safety, cost, and regulatory compliance drives redundancy decisions. Consider the probability of a controller failure and the potential outcomes that may result. Processes where failures could result in loss of life, equipment, or expensive materials often include redundancy and triple modular redundancy. DCS technology typically has been the preferred choice for high-risk unit process applications where redundancy is necessary for product integrity. However, for safety interlocking and SIL rating per IEC 61511 and 61508, the PLC is the most often used and cost-effective solution. Also, given the cost of redundant DCSs, a hybrid approach is becoming a more popular and economical alternative to a single controller technology. For example, PLCs are used in high-risk machine-level process phases and for safety interlocking, while the DCS is used in high-risk plant-level process phases.

[h3]Interoperability[/h3]

This is a key consideration relative to legacy systems in terms of understanding whether the network environment is open or closed to third party and non-native devices and protocols. Despite the standardization of programming languages and network protocols, both DCS and PLC maintain mostly proprietary architecture. Many applications today involve retrofitting to an existing network; therefore, it is important to know the devices’ interfacing capabilities and protocols.

[h3]Training[/h3]

Assessing the skill levels of technicians, operators, and plant engineers is needed to determine the learning curve. If personnel already know PLC ladder logic control, moving from one PLC platform to another will be easily accomplished. DCSs, however, are more complex, requiring a longer learning curve and more extensive skill sets to properly configure a system. The learning curve affects day-to-day operation, which factors into the cost to deploy and maintain the system.

[row]

[col width=”four”] [/col]

[/col]

[col width=”four”] [/col]

[/col]

[col width=”four”] [/col]

[/col]

[/row]

[h2]COMMON APPLICATIONS AND GUIDELINES[/h2]

Following are some common controller applications and general guidelines for selecting the most effective controller technology for each:

[h3]OEM Controller Units[/h3]

These represent a smaller part of a larger system, such as skid mounted equipment. In the water industry, common applications for skid-mounted PLC usage include grit removal equipment, aeration systems, pumps, filters, centrifuges and filter presses. OEM controller units tend to be cost-sensitive applications that do not require extensive reprogramming, which make them more conducive to PLC technology for its lower installation costs, easier maintenance, and attractive total cost of ownership (TCO).

[h3]Applications with Large Complex Processes[/h3]

These processes (for example, chemical, power, and pulp and paper) tend to include highly complex control loop interactions and batch control, and require high redundancy for process uptime, making DCS technology a preferred choice given its robust capabilities. Today, PLCs often manage many of the areas within these large industrial sites and communicate to the DCS for operational control.

[h3]Applications with Motion and Interlocking Processes[/h3]

This application category—examples of which are conveying systems and machine and motor control—includes numerous discrete control devices such as proximity switches and motion detectors. PLC technology tends to be more compatible with such operations, particularly since many may undergo ongoing lineup changes.

[h2]KEY CONSIDERATIONS WHEN SELECTING A CONTROL PLATFORM[/h2]

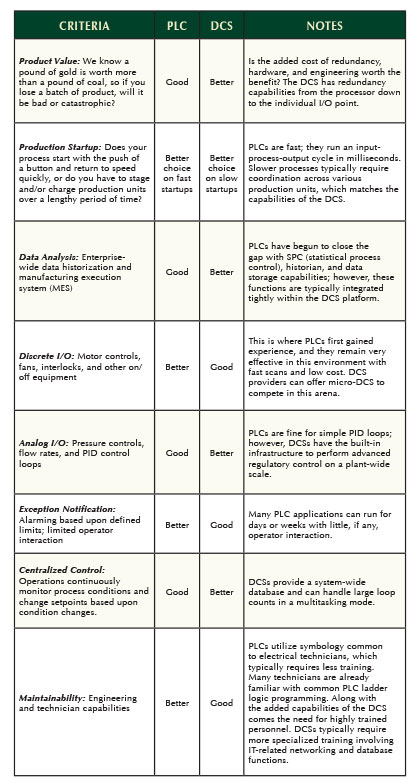

The table provides general guidance for narrowing down the selection of controller platforms and is not intended to replace a consultation by a trained knowledgeable professional.

The table provides general guidance for narrowing down the selection of controller platforms and is not intended to replace a consultation by a trained knowledgeable professional.

[h2]TRENDS TO WATCH IN CONTROLLER TECHNOLOGY[/h2]

In part 1 of this article, we examined two examples of poorly managed complexity and poorly managed technology for DCS and PLC use-case scenarios. Now, let’s look ahead to some trends in controller technology.

The paradigm of specifying PLCs only for discrete control applications and DCS for proportional-integral-derivative (PID) loop control no longer applies. Driven by advancements in microprocessors and COTS, technologies have converged, and in some cases, the differences between the two are barely discernible. As a result, it is imperative to fully understand the process application to ascertain the best control strategy for the end user. Each technology and each vendor has a sweet spot. This is what needs to be fleshed out and matched with the operational requirements.

Today we are beginning to see secure cloud computing technologies, virtualization, and mesh networks migrating from the IT world to the realm of process control. The convergence of PLC and DCS will continue, and many of the functions that have been the domain of control systems will be pushed to intelligent field devices, including the use of more bus and wireless I/O.

These trends will continue slowly. Production facilities are wary of leading edge technologies; they will maintain a conservative viewpoint and continue to demand their control systems are proven technologies.

Convergence

Convergence of the two technologies precipitates the need to consider application and customer requirements. Often the customer’s needs and wants go beyond the application itself and involve a business requirement such as lower TCO or flexibility to meet changing market demands. A hybrid system can often address manufacturing requirements and business needs. For example, apply DCS technology where process material risk and cost of downtime are high, and PLC technology where changes in output or product variation require flexibility.

Both technologies continue to trend away from proprietary systems toward open standards. PLC technology, for example, uses IEC 61131-3, which standardizes programming languages. Standardization contributes to cost and time savings by making PLCs more interoperable. DCS technology, too, has adopted PC architecture and open networking standards such as Ethernet and Fieldbus. Taken a step further, it’s possible to interface with today’s DCSs or PLC systems from a laptop or iPad.

Collaborative Efforts

As industrial control systems become more distributed, interconnected, and reliant on the Internet, they become targets for cyberattacks. Many may recall the Stuxnet worm that infected SCADA systems. The process control system can no longer be considered an isolated island of automation. It is an integral part of the business unit and must meet the same rigors of an enterprise’s risk management and IT security/ business continuity and disaster recovery plan. The lines become blurred between the IT department and operations, each with unique risk requirements relative to safety, availability, and fault tolerance.

It is not always the faceless hacker attempting to create chaos as a political statement or for bragging rights. Harm can originate from disgruntled employees as well as the unintentional introduction of malware. These scenarios must become part of an organization’s business continuity and disaster recovery plan.

[h2]CONCLUSION AND SUMMARY

When designing, specifying, and sourcing controller technology, keep in mind that it’s no longer necessary to choose one or the other. On the contrary, for many applications, a hybrid approach can optimize cost, efficiency, and performance without compromising safety, security, or regulatory compliance.

Trends including advances in microprocessor technology, open standards for interoperability, and web-based applications are driving the need for new and different approaches to applying existing controller technologies. The result can be a more cost-effective control system from an initial cost and overall operating cost perspective, as well as from improved efficiencies. ■

[divider]

ABOUT THE AUTHOR

Jim Hazelwood is a project engineer at Revere Control. He has spent the past thirty years helping manufacturing companies improve plant throughput and reduce operational costs through the design of robust automation systems. Bill Butler is a business development manager at Revere Control Systems. He is a forty-five-year veteran of the manufacturing automation controls industry and has helped manufacturers optimize their assets by designing integrated control systems.

________________________________________________________________________

MODERN PUMPING TODAY, April 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()