When Anheuser-Busch InBev was seeking to reduce labor costs at one of its thirty-six Chinese brewing facilities, it turned to Bredel hose pumps from Watson-Marlow Fluid Technology Group (WMFTG). The pump automated previously manual operations, reducing manual labor and filter press downtime, offering considerable cost savings. At the same time, the new pump technology also offers an improved environmental solution. The company now has plans to modify three additional filter presses to use the hose pumps.

PRODUCTION METHODS RESULT IN HIGH MANUAL LABOR COSTS

Since Anheuser-Busch InBev first entered the Chinese market in 1984, the company has established thirty-six plants and hired around 25,000 employees. One of the largest is the Putian brewery in Fujian province, with annual beer output of about 1,000,000 tons (907,185 tonnes).

The plant’s production method still relies largely on manual processes, including four plate-and-frame filter presses for filtration of diatomaceous earth. These presses added considerably to labor costs. First of all, it took workers to collect waste diatomaceous earth after it was emitted into stainless steel boxes under the filters. Secondly, two workers were needed to shovel the diatomaceous earth into bags, which were then carried to a truck for appropriate disposal.

Not only was the process laborious and time consuming, but because shoveling the diatomaceous earth into bags relied on human judgment, some of the material always ended up on the brewery floor. Workers would have to spend extra time washing down the area, which had a big impact on production planning and scheduling, particularly in peak season periods.

HOSE PUMPS PROVIDE SOLUTION

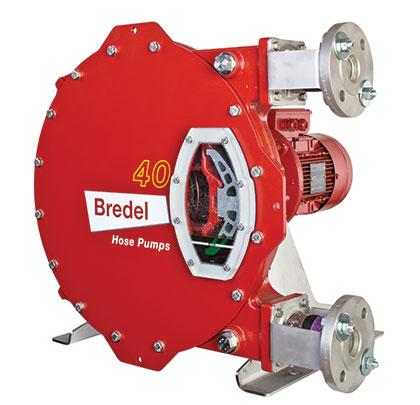

For a solution to the problem, the facility turned to WMFTG, which already had fourteen successful applications in the diatomaceous earth and PVPP (polyvinylpolypyrrolidone) dosing process using Bredel hose pumps.

An application engineer suggested that the customer install a cone-shaped tray with a screw propeller underneath the filter to feed the waste diatomaceous earth to a Bredel hose pump. From there the diatomaceous earth could be pumped to a collection tank stand outside of the plate and then loaded onto a truck for transfer to the designated disposal point.

The idea was implemented on one of the filter, and proved to be successful. Operations personnel estimate that the Bredel hose pump has saved the efforts of two workers and the associated labor time. Furthermore, the pump can be set to run at the same time as diatom unloading in the press, thus reducing filter downtime and helping to maintain production schedules. The pump has also reduced the impact to the environment since there is no longer any requirement for cleaning water.

In addition, there have been no maintenance requirements since the pump began operations. As a result, the Putian facility of Anheuser-Busch InBev is now finalizing plans to modify its three other filter presses on site. ◆

Chuck Treutel is sales manager for Watson-Marlow Fluid Technology Group and can be reached at 608.883.6851 or via email chuck.treutel@wmftg.com. WMFTG is the world leader in niche peristaltic and sinusoidal pumps and associated fluid path technologies. Founded on nearly sixty years of supplying engineering and process expertise and with over one million pumps installed worldwide, our pumps are tried, tested and proven to deliver. For more information, visit www.watson-marlow.com.

____________________________________________

MODERN PUMPING TODAY, June 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()