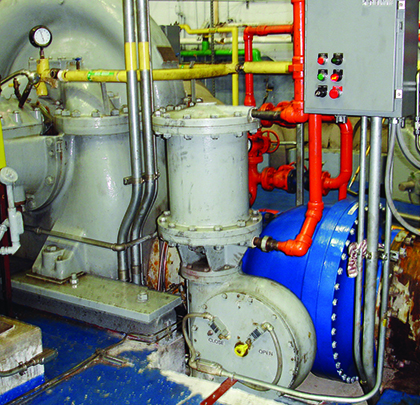

Built in 1911, the Roseland Pumping Station is located on the south side of Chicago and is the largest of three pumping stations in the city. Roseland Station transports an average of 39 billion gallons (147 billion liters) of potable water annually, which is then pumped to over 750,000 Chicagoans throughout the south side of the city and southern suburbs. The station houses five pumps and each pump has a 24-inch (60.96 centimeter) metal-seated ball valve. One of these metal-seated valves was leaking and sticking. Although the seat had been recently replaced, it continued to stick and the overall condition of the valve was progressively deteriorating, thus requiring a full replacement. Fortunately, the perfect solution was only 20 miles (32.19 kilometers) away.

TRUST BUILT THROUGH TESTING

Val-Matic Valve and Mfg. Corp is located in Elmhurst, Illinois, and is a leader in designing, manufacturing and marketing of quarter turn shut-off valves, air valves, check valves and foot valves for municipal, water/wastewater, power, industrial, and HVAC building applications. The Chicago Department of Water met with Val-Matic to discuss the engineering behind the Ener•G® AWWA rubber seated ball valve and to witness ball valve testing. Both parties were confident the 24-inch (60.96 centimeter) double seated AWWA Class 150 Ener•G® ball valve would be the ideal valve for the application. The Department of Water Management was impressed by the key design features of Val-Matic’s Ball Valve and the short leadtime allowed a quick replacement for the failing valve.

According to Raymond Rutz, foreman of machinists at the Department of Water Management, “The response time was phenomenal. We witnessed the ball valve testing, which was a bonus, and we were able to work with Val-Matic in creating a solution that suited our needs.”

Significant selling points were the Ener•G® Ball Valve’s compatibility with the existing actuator, easily adjustable and replaceable seat, and flow characteristics equivalent to the existing metal-seated ball valve.

EASE OF SERVICEABILITY

One of the trademark features of the Ener•G® Ball Valve is ease of serviceability. “Replace the seats and hold on to the valves? Boy, these guys were really thinking,” muses Rutz. Adjustment of the resilient seat is easily performed with a torque wrench, unlike many similar valves, which require hypodermic needles or pressure pots for adjustment.

In addition, the valve is coated internally and externally with NSF 61 fusion bonded epoxy per AWWA C550. The materials and engineering are specifically designed for continuous service and the fusion bonded epoxy coating is able to withstand the rigors of most liquid applications.

The rubber seated ball valve was developed with over fifty years of combined engineering experience and was designed for tight seating, long life, and energy savings. The Ener•G® Ball Valve utilizes resilient seat technology and when fully open the seat is completely out of the flow stream. The seat is fully adjustable or replaceable with minimal downtime and is available in single or double-seated for sealing in one or two directions.

Ener•G® AWWA rubber seated ball valve

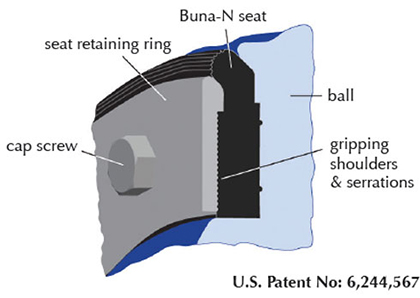

TRI-LOC SEAT RETENTION SYSTEM

The Ener•G® ball valve seat utilizes the Tri-Loc™ seat retention system and is secured by three methods: clamp force, through-bolting, and opposing registers in the ball and seat-retaining ring. Tightening the Nylok cap screws provides the clamp force and these same screws provide through-bolting seat retention by passing through the precision molded holes in the Buna-N seat. Finally, molded shoulders in the seat are captured by registers and serrations in the ball and the retaining ring preventing outward movement of the seat (see figure 1).

NO GREENER VALVE

In addition to being easily serviced, the Ener•G® Ball Valve offers long-term energy savings. When fully open, the Ener•G® Ball Valve provides a 100 percent clear flow area equal to the valve size. Thus, the valve headloss is equal to an equivalent length of pipe and will represent a significant savings in pumping costs. It consumes the least amount of energy of any control valve (less than 1 percent of the energy of a globe-style control valve). For headloss calculation and energy savings projections, Val-Matic features an Energy Cost Calculator on their website. Users can input data specific to their application and compare the projected energy savings of the Ener•G® Ball Valve to various check, pump control and shut-off valves. To conserve energy and reduce costs, there is no greener valve.

THE FIRST OF MANY

According to Rutz, he was impressed with the availability of the Ener•G® Ball Valve, the design features and the long-term cost savings, and the ability to incorporate the valve into an existing application.

“As you go down the line, more seats are beginning to show signs of sticking, so this valve replacement is the first of many to com,” Rutz adds. “We look forward to working with Val-Matic to replace ancient equipment and albatrosses throughout the station.”

The Ener•G® AWWA Rubber Seated Ball Valve is certified to rigorous pressure and cycle proof design tests per AWWA C507. Manufacturing technology uses automated process control in the foundry and ISO 9001-2008 controlled manufacturing processes. Every valve is tested in accordance with AWWA C507 on automated hydraulic test rigs with calibrated gauges. ■

_________________________________________________________________________

ABOUT THE AUTHOR

Alissa Kantola is the marketing project coordinator for Val-Matic Valve and Mfg. Corp. Val-Matic Valve and Mfg. Corp. incorporates the latest in valve technology to assure a high-quality valve that will provide a long service life. For more information regarding the Ener•G® Ball Valve or to take advantage of the Energy Cost Calculator, please visit www.valmatic.com.

_________________________________________________________________________

MODERN PUMPING TODAY, May 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()