Veolia Water North America is a leading provider of water and wastewater services for municipalities, government entities, business and industry. In 1985, Veolia Water assumed the responsibility for operating, maintaining, and managing the Wilmington, Delaware solids processing facilities.

In 1998, the company was awarded a new twenty-year, $224 million contract to manage the entire wastewater treatment process for the city and outlying served areas. That project included a 134-MGD high-rate activated sludge plant, three pump stations, industrial pretreatment program, industrial leachate and 11,000 dry-tons-per-day sludge disposal. Like many other older industrial cities, Wilmington has a “combined” sewer system, meaning that both sewage and storm water share the same pipes as they flow to the Wilmington Wastewater Treatment Facility and eventually back into the Delaware River.

Veolia sought an improved pumping solution for two different sludge handling applications including transporting thickened sludge and digester recirculation. The company wanted to reduce its $250,000 annual pumps maintenance budget and the downtime associated with the issue-prone pumps it was previously using. Veolia turned to NETZSCH to provide an improved pumping solution.

A LOW MAINTENANCE SOLUTION FOR A PROBLEMATIC THICKENED SLUDGE LINE

According to plant operators, the two progressing cavity pumps in use in the thickened sludge transport application had pressure problems due to their inferior design. These pumps featured a very high angularity as a result of a short coupling rod and only grease-lubricated joints.

“One pump had a small dogbone, and it would snap all the time. I would say that the longest running pumps we had would last about one year. We even had one pump that would go down every three months,” says Aleksey Reznik, the plant general manager for Veolia North America.

Veolia decided that the Wilmington plant needed a change, and sought an improved thickened sludge pumping solution from NETZSCH.

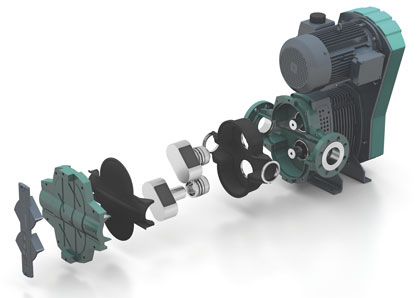

“We had read a good report on the NETZSCH lobe pump and did a ninety-day test on our worst application, which was a feed line to our digesters with 3 to 4 percent solids at 60 psi pressure,” Reznik says. “We installed the four-inch NETZSCH Tornado® T2 pump and it has been running continuously for two years. We’ve replaced two seals in that time, but with the easy access through the faceplate, that was a very simple operation.”

The first NETZSCH Tornado® T2 pump replaced a competitor’s progressing cavity pump with an inferior design. The plant operators also replaced a second progressing cavity pump from the same manufacturer but with a traditionally designed rotary lobe pump from a NETZSCH competitor. However, that rotary lobe pump was not able to handle this heavy-duty application and was later also replaced by a NETZSCH Tornado® T2 rotary lobe pump with a full-service-in-place (FSIP) design to minimize downtime. To date, the two pumps are working 24/7 in that application, providing a low maintenance solution in this critical plant operation.

DIGESTER CIRCULATION LINE NOW RUNNING ALMOST MAINTENANCE FREE

In addition to maintenance issues in the thickened sludge line, Veolia was also experiencing gas bounding problems in some of the Wilmington plant’s sludge digesters.

“Before we installed the NETZSCH rotary lobe pumps, we had been using recessed impeller centrifugal pumps for years. There was a very long suction line, gas came through and the pumps continuously lost prime. When the pump lost prime, we had to back flush the line by pumping water in, which is something you don’t want to do in this sludge application,” Frank DiPeitrapaul, a maintenance engineer at the treatment plant, says.

“Plus, we have a small staff and this issue was creating havoc with our maintenance schedule.”

NETZSCH rotary lobe pumps were also selected to replace the problematic pumps in this application.

“We have two NETZSCH pumps now working in this process. The first is a four-inch rotary lobe pump. Also, since our digesters are remotely controlled by data, they open and close automatically and there is some back-pressure as you go down the line. As a result of this higher pressure, we’ve installed a NETZSCH six-inch pump down the line.”

DiPeitrapaul noted that the NETZSCH pumps have been running almost six months in the sludge circulation application without any downtime and have completely solved the air-bounding problem.

“Not only has the air-bounding problem been eliminated, but also, since the pump is belt-driven, there is no oil. We don’t have to worry about putting in the wrong oil or running out of oil. There is a small container that puts a small amount of oil on the seal, but that’s it,” DiPeitrapaul says.

According to DiPeitrapaul, the plant maintenance staff regularly checks the Tornado® T2 pumps to see if the lobes need to be changed, but that they have not yet had to since the lobes don’t show enough wear.

“In terms of maintenance, our team loves the NETZSCH pumps,” he says. “The design is very simple and it takes about fifteen minutes to check them over. Even when we had to repair the seals, it was easy because the design ensures that you don’t have to pull the pumps out for that kind of repair. Additionally, the small footprint of the NETZSCH pumps has been beneficial in our plant.” ◆

For More Information: Netzsch Pumps and Systems has served markets worldwide for more than sixty years, providing customized, sophisticated solutions for applications in every industry type. With a workforce of more than 2,000, Netzsch Pumps and Systems is the largest business unit in the Netzsch Group. For more information, visit www.netzsch.com.

____________________________________________

MODERN PUMPING TODAY, November 2016

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()