NuTerra installed BCR Environmental’s (BCR) Neutralizer™ systems at each of Clay County Utility Authority’s (CCUA) four wastewater treatment plants (WWTPs) between 2006 and 2010. The streamlined, patented two-stage Neutralizer system treats waste activated sludge and produces Class A residuals for unrestricted land application in just a matter of hours.

CHALLENGING SITUATION

CCUA’s four regional WWTPs in the Jacksonville, Florida, area were treating secondary sludge through an antiquated aerobic digestion process and hauling Class B residuals either to the landfill or land application sites. In an effort to upgrade their process to a Class AA/EQ biosolids treatment solution at all WWTPs, CCUA commissioned Mittauer and Associates, Inc. to conduct a comprehensive engineering study to evaluate the initial capital, operational, and maintenance costs of various treatment options along with qualitative benefits for commonly used Class A and Class B biosolids treatment options. The findings would help the city address these challenges:

- Escalating energy costs

- Need to control odor

- Hauling and disposal costs

- Stringent environmental regulations

NuTerra implemented BCR’s Neutralizer solution, which incorporates Huber’s easy-to-operate HMI and disk thickeners that simplify use and reduce energy consumption and costs.

STUDY POINTS TO NUTERRA’S RECOMMENDED NEUTRALIZER SYSTEM

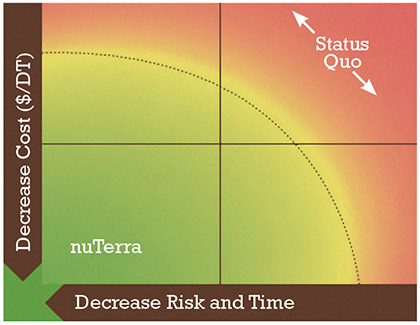

The study compared NuTerra’s recommended Neutralizer solution to dryer systems, lime stabilization, anaerobic digestion, and Class B aerobic digestion. The findings concluded that the Neutralizer system was the most economical and environmentally responsible option. The simple, two-stage chemical process safely meets pathogen and vector attraction requirements as defined by the CFR 40 Part 503 and is approved by the U.S. EPA as a Process to Further Reduce Pathogens (PFRP). It requires a minimal footprint and can be easily integrated into a WWTP’s existing infrastructure.

BCR NEUTRALIZER SOLUTION DELIVERS

The BCR Neutralizer system that NuTerra implemented features a control system and monitoring devices that record process parameters and ensure the consistent, documented generation of high quality Class AA/EQ biosolid material. NuTerra installed Neutralizer systems between 2006 and 2010 at all four WWTPs, ranging from 2 million gallons to 5 million gallons average daily flow.

Following installation of the fourth Neutralizer system, 100 percent of CCUA’s biosolids met Class AA/ EQ standards as defined by the CFR 40 Part 503. The material is registered as a commercial fertilizer with the Florida Department of Agriculture, and is distributed to local users. NuTerra’s solution provided multiple advantages over CCUA’s previous treatment system, including:

- 43 percent reduction in annual operating costs for biosolids treatment and disposition

- 92 percent decrease in energy costs associated with biosolids treatment

Odor-free residuals - Enhanced nutrient removal that meets strict new standards for nutrient discharge

- Adjustable pH to suit client needs, with an extremely low P index (phosphorous leachability)—0.1 Phosphorous Source Coefficient in a study performed by Penn State University

YEAR ONE: OPERATING PERFORMANCE SOARS, ENERGY USAGE AND COSTS PLUMMET

In 2009 CCUA conducted an internal analysis of the NuTerra project’s annual operating cost at the three locations that had been completed at the time, compared with the annual operating costs of digestion and hauling incurred by those sites. Monitored by a single control panel, the new, highly automated, and simple-to-operate system reduced CCUA’s annual biosolids management operating costs by approximately $750,000. What’s more, since day one, the system had reliably treated over 18,000 tons of biosolids with consistent results.

Instead of using energy-intensive treatment (digesters, dryers, incinerators, gasifiers) required by digestion, the Neutralizer system relies on chemistry. The entire Neutralizer process uses energy-efficient equipment to minimize electrical consumption by 90 to 95 percent from other Class A biosolids treatment options

A TRUSTED PARTNER

NuTerra designs, builds, and assumes full project accountability for long-term, sustainable wastewater treatment/organic waste and biosolids management solutions that deliver municipalities on average savings of 40-plus percent in operating costs and 90-plus percent in energy consumption. These partnerships meet capital and operating expense constraints, assure regulatory compliance, buoy public sentiment, and enhance environmental stewardship.

Only provider using scalable, lowest-cost solutions certified by the U.S. EPA that provide high quality end products for beneficial reuse/land application.

Only company with economically viable solutions for <15MGD/<15 DTPD operations.

Only fully integrated platform with proven technologies and 100 percent project success.

Only progressive project delivery approach with financial and risk analysis models designed specifically for biosolids and organics operations/management. ◆

About The Author

Aaron Zahn is president and CEO of NuTerra. NuTerra designs, builds, and assumes full project accountability for long-term, sustainable wastewater treatment/organic waste/biosolids management solutions that deliver municipalities on average savings of 40-plus percent in operating costs and 90-plus percent in energy consumption. For more information, visit www.nuterra.green or call 904.819.9170.

____________________________________________

MODERN PUMPING TODAY, December 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()