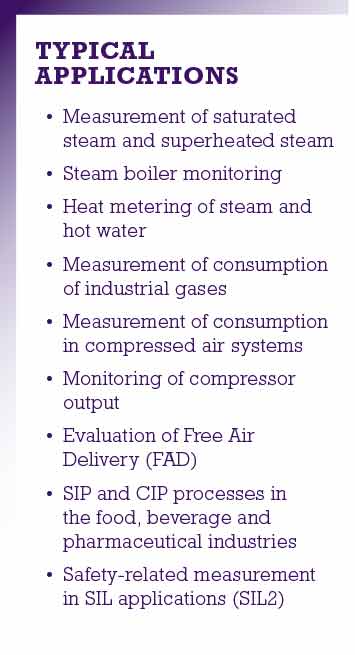

Operators searching for reliable flow measurements in advanced energy management systems have a new tool at their disposal. Used to measure both conducting and non-conducting liquids, gases and steam, the new Optiswirl 4200 vortex flowmeter can be used for internal monitoring of energy flows for saturated and superheated steam or hot water, and heat metering applications. It is also a perfect choice for such applications as steam boiler monitoring, burner consumption measurement, or compressed air network monitoring, including free air delivery (FAD) applications.

IN WITH THE NEW

Equipped with comprehensive communication options, and designed in accordance with international IEC 61508 functional safety standards, this flowmeter is a major update to the original 4070 model. With one temperature sensor integrated as standard, the device can be installed as a heat meter in the feed line directly connected with an external temperature sensor in the return line. The gross and net heat calculation can be fed into a distributed control system (DCS) to support advanced energy management.

FLEXIBLE OPTIONS FOR VARYING NEEDS

The all-in-one solution features integrated pressure and temperature compensation, and can perform both gross heat calculations for steam and net heat calculation for steam and condensate (hot water). The Optiswirl 4200 is available in a remote version equipped with a field housing converter with a connection cable up to 164 feet (50 meters). Temperature and pressure compensation options are also available, which enable calculation of standard flow volume under fluctuating pressures and temperatures. By measurement of flow, temperature, and pressure in one 2-wire-device, the line has to be opened only once for installation.

In addition to the standard sensor range, another available option features an integrated reduction of nominal diameter up to two sizes, ideal for space-saving installations and large measuring spans. A dual version with two independent sensors and two signal converters is also available for multiproduct pipelines, redundant measurement or increased safety demands.

ENHANCED ACCURACY

The Optiswirl 4200 also includes a variety of electronics enhancements. The device is now equipped with a new advanced vortex frequency detection (AVFD) function, as well as a newly developed signal converter (VFC 200), with advanced signal processing and filtering that suppresses interferences and disturbances in the pick-up signal and filters out signals other than the relevant frequency band. Redundant data management prevents loss of calibration and configuration data when changing electronics or display. ◆

Sandy Olley is marketing communications manager for Krohne, Inc., a worldwide technological leader in the development, manufacture and distribution of accurate, reliable and cost-effective measuring instruments for the process industries. For more information call 800.FLOWING, email info@krohne.com, or visit www.us.krohne.com.

____________________________________________

MODERN PUMPING TODAY, June 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()