Docupak LLC, a full service marketing company headquartered in Alabaster, Alabama, has reduced chemical usage by a third and removed all scale from its cooling tower at its plant after installing the patented, award-winning Scalewatcher computerized, electronic water-conditioner from Scalewatcher North America. In addition there are no longer signs of algae growth on the cooling tower louvres.

ELIMINATING LIMESCALE AND ALGAE

Founded in 1998, Docupak, the operating name of Document and Packaging Brokers Inc., develops and distributes materials for businesses nationwide. In addition to its headquarters in Alabaster, Alabama, the company also operates a further plant in Alexandria, Virginia, and has sales offices in Atlanta, Chicago, Cincinnati, Dallas, Los Angeles, Tampa, and Washington, D.C.

Aware that health agencies continually draw attention to the risks of limescale and algae in cooling towers and wanting to reduce the use of chemicals in the cooling tower, Plant Manager Anthony Kinstley decided to install the Scalewatcher electronic water-conditioner through local dealer, Al Chatham of Water Processing and Well Supply in Harpersville, Alabama. An industrial Scalewatcher was installed on to the water-feed line to the building and then a further unit was specifically fitted on to the recirculation line of the cooling tower.

“Since using the system the scaling on our cooling tower has been eliminated and we currently use only a third of the original chemicals intended for the water treatment within our system”, says Anthony Kinstley.

ENVIRONMENTALLY FRIENDLY SOLUTION

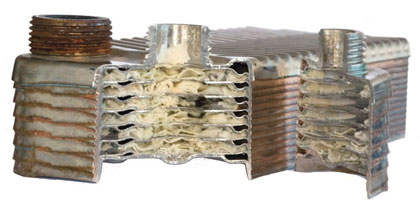

Many air conditioning and refrigeration plant systems are water-cooled. The heat generated by cooling coils is removed by water, which is passed through a water-cooling tower. These are recirculating systems, which operate at temperatures ideal for bacterial and algae growth, and have plentiful supplies of nutrients. In cooling towers, temperature, water hardness, pH, scale and corrosion are all factors, which increase the chance of biofilms, algae, and Legionella colonization.

The environmentally friendly Scalewatcher provides a permanent solution to hard water problems without the need of chemicals, salt or maintenance. It works by producing a varying electronically applied force field, induced by a coil wrapped around the outside of the pipework, which keeps the minerals in suspension and thus prevents limescale forming. The water’s increased solubility enables it to dissolve existing scale, which is gradually washed away.

Scalewatcher models are based on continuous research and over twenty-five years experience and expertise as market leaders in electronic scale control with countless units sold worldwide. The patented Scalewatcher systems are capable of treating pipe sizes from 1 to 120 inches (25.4 millimeters to 3 meters). All Scalewatcher systems come with a full performance guarantee and are shipped free throughout North America. ◆

Jan de Baat Doelman is president of Scalewatcher North America Inc. The Scalewatcher is an environmentally friendly alternative to chemical and mechanical descaling. Launched in the 1980s it has successfully treated hard water problems for industrial manufacturers as well as water companies, oil producers, farmers, horticulturists, shipping companies, shopping centers, school, universities and government establishments. For more information, call 610.932.6888, email sales@scalewatcher.com, or visit www.scalewatcher.com.

____________________________________________

MODERN PUMPING TODAY, May 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()