In today’s complex and frequently rugged process plant environments, liquid pumps are often over-worked and under-protected from adverse operating conditions. Many pumps run nearly non-stop 24-hours a day over multiple shifts. Poor operating conditions can reduce pump performance, require extra maintenance, shorten their lives and increase costs.

Unexpectedly losing a pump is often an expensive or even a dangerous problem in a chemical plant. The results of a pump failure potentially range from the loss of product in sensitive pharmaceutical batch control applications to damage to other nearby equipment from pressure build-up of material that isn’t moving or even to safety hazards when a pump fails to shut-down and literally burns-up in the presence of combustible materials. It really pays to protect and care properly for your pumps.

ADVERSE PUMP OPERATING CONDITIONS

Two of the more common problems that can negatively affect pumps are wet/dry conditions and flow disturbances—both of which are preventable.

Nothing can damage a liquid pump faster than the build-up of heat from dry running conditions, which occurs when liquid stops flowing into the line or the pump. When the liquid isn’t there to provide cooling, the heat can destroy a pump’s bearings. If repair is even possible, it is going to be a very expensive proposition.

For proper and efficient operation, pumps require a stable upstream flow profile in the pipeline before liquid enters the pump. When elbows, valves or other equipment are installed too closely to a pump, these other devices can create swirl and velocity profile distortion in the pipeline. These disturbances can result in excess noise and cavitations, resulting in reduced bearing life.

WET/DRY CONDITIONS

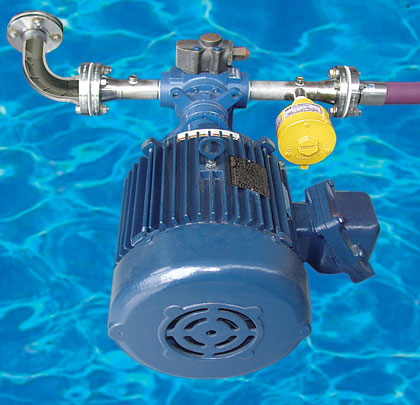

Installing a point flow/level switch (figure 1) in your pump’s process loop eliminates the damage caused by a pump running dry. Point flow/level switches are capable of detecting not only a low flow situation, but also detecting a dry running condition. This capability allows the control system or operator to take corrective measures before the bearings of the pumps are overheated and fail. Among the many types of point flow/level switches available is FCI’s FlexSwitch® FLT series, which offers dual alarm capability (see figure 2).

Alarm 1 will detect a low-flow situation anywhere between 0.01 and 3 feet per second (FPS) (0.003 to 0.9 meters per second MPS). This low flow alarm can be regarded as a pre-warning signal for the control system or operator. The system or operator can then decide to keep the pump running or to shut it down.

Alarm 2 occurs if the feed line to the pump is running dry, which would be an emergency signal to shut down the pump immediately because the bearings now see gas instead of a liquid as a heat transfer media. In this case, the temperature of the bearings may rise very fast. The flow switch prevents permanent damage to the pump’s bearings that will require an overhaul of the pump before more damage occurs.

This flow switch is a dual-function instrument that indicates both flow and temperature, or level and temperature sensing in a single device. Available in either insertion or in-line styles for both pipe or tube installation, a single switch measures and monitors flow or level and temperature simultaneously with excellent accuracy and reliability. Dual 6A relay outputs are standard and are assignable to flow, level or temperature.

The switch operates over a wide flow range, making it suitable for liquid pump protection. Switch point accuracy of +2 percent and measurement repeatability of +0.5 percent of reading ensures accurate, reliable operation. The standard configuration withstands operating temperatures up to 350 degrees Fahrenheit (177 degrees Celsius), and optional versions are available up to 850 degrees Fahrenheit (454 degrees Celsius).

FLOW DISTURBANCES

Installing an elbow flow conditioner upstream from your pump will ensure an optimal flow profile for efficient operation. Isolating the effects of velocity profile distortions, turbulence, swirl, and other flow anomalies in your pipeline will result in a repeatable, symmetric, and swirl-free velocity profile with minimal pressure loss. Creating a relatively more benign operating environment helps increase pump life. The conditioned flow stream enters the pump’s impeller in a uniform and equally distributed pattern, optimizing pump efficiency and extending bearing life while at the same time decreasing noise and cavitation.

If your plant is short on real estate with confined and non-ideal pipe configurations, the elbow flow conditioner (figure 3) will eliminate all upstream straight run requirements for pumps, compressors, flow meters, and other critical process equipment.

Tab type flow conditioners, such as those provided by the Vortab Company, have proved successful in these applications. Other flow conditioning technology choices, including tube bundles, honeycombs, and perforated plates, may also be considered depending upon the specifics of the application. The elbow flow conditioner’s profile conditioning tabs produce rapid cross stream mixing, forcing higher velocity regions to mix with lower velocity regions. The shape of the resultant velocity profile is “flat” and repeatable regardless of the close coupled upstream flow disturbances. Incorporating anti-swirl mechanisms into the design eliminates swirl typically seen exiting 90-degree elbows. The result is a flow stream that enters the pump in such a way that it maximizes the efficiency of its operation and reduces stress. In addition, the tapered design of the anti-swirl and profile conditioning tabs make them immune to fouling or clogging.

CONCLUSIONS

If liquid pumps are an important part of your process, then take the time and make the investment to protect them from dry running conditions and flow disturbances. You’ll not only ensure that your pump lasts longer, but you just might improve the efficiency of your process, reduce unnecessary maintenance costs and prevent shut-downs or accidents. Take care of your pump and it will take good care of you.

_______________________________________________________________________

ABOUT THE AUTHOR

Don Lundberg is a senior engineer at Fluid Components International. For more information about FCI’s FlexSwitch® FLT series or Flow Conditioners, visit www.fluidcomponents.com.

_______________________________________________________________________

MODERN PUMPING TODAY, March 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!