According to the Wine Institute, 330 million cases of wine were consumed in 2010 alone. From 2010 to 2011, U.S. wine consumption increased 4.5 percent to make the United States the world’s leading wine-consuming nation. And according to Vinexpo.com, the global wine and spirits industry is now a $170-billion market—approximately the same size as the cosmetics industry. In 2014, Vinexpo.com projects the global wine market to approach $200 billion.

All this paints one tasty picture: the booming wine industry has exploded with countries like China and Russia positioning themselves as prominent players approaching the ranks of world leaders like the United States, France, and Italy. Around the globe, there is a push to penetrate this growing market. For this, processes that produce both quality and profitability are needed.

Wilden® AODD pumps deliver performance and reliability in a wide array of winemaking processes, including product transfer, filtration and bottling, and the unloading of trucks, tank wagons and ships.

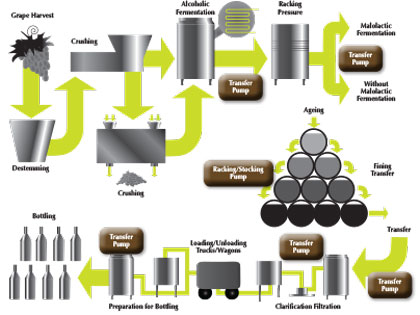

WINEMAKING PROCESS

The process of winemaking involves numerous stages that must be followed precisely to ensure the highest quality wine, starting with the grapes being harvested, taken into a winery and then prepared for fermentation. At this stage, red wine is created during the fermentation of the pulp (or “must”) and skins of the red or black grapes, which gives the wine its color. White wine, on the other hand, does not include the grape skins in the fermentation process; only the juices are extracted.

To start primary fermentation, a process that typically takes between one to two weeks, yeast is added which converts the sugars in the grape juice into alcohol and carbon dioxide, which then evaporates into the atmosphere. The produced liquid, which is known as “free wine,” is then pumped into tanks and the skins are pressed in order to extract the remaining wine and juice. This wine, known as the “press wine,” can be added to the free wine to bring more character and longevity to the wine.

Secondary fermentation is the next step, which is the bacterial fermentation involving the conversion of malic acid to lactic acid. This decreases the amount of acid in the wine and softens the taste. The wine can then be transferred to oak barrels for maturation, with further adjustments to taste and color being made prior to filtering and bottling.

Various pieces of equipment play a critical role in the winemaking process, perhaps none as critical as the role of pumps. Pumps are used for wine transfer, filtration/bottling, unloading trucks, unloading tank wagons and unloading ships, to name a few applications (see diagram 1).

When selecting the pump technology that is best suited for wine-handling and transfer, operators should identify a technology that not only has shear-sensitivity (the ability to move the wine without damaging or “shearing” the delicate product), and deadhead capabilities (the ability to start and stop the pumping process instantly without subjecting the wine to heat or damage from moving pump components or bypass relief valves), but can also safely transfer large solids (the “must”) with strong suction lift.

In order to meet growing demand while producing desired products, global winemakers are turning more and more to Wilden® AODD pumps for use in their precise winemaking processes.

THE EARLY PUMPING OPTIONS

Flexible impeller pumps and piston pumps were two of the first pumps to be used in winemaking. Flexible impeller pumps were considered the ideal choice for smaller wineries due to their ruggedness and affordability, while piston pumps hold the distinction of being one of the first pumps used in the production of high-end wines.

But their limitations became obvious to the wine community, starting with flexible impeller pumps. Although inexpensive, these pumps cannot move solids, which eliminates the possibility of utilizing these pumps in the must-transfer process. Also, the flexible impeller pump cannot run dry. If they do run dry, the impeller will overheat, damaging the pump, as well as the quality of the wine. Piston pumps, on the other hand, are known for their low-shear pumping characteristics, but the weight of these pumps can present safety issues for personnel, while the presence of seals creates an opportunity for leaks and product contamination.

Due to these issues, the industry began transitioning to other evolving pump technologies that offered the necessary characteristics to ensure the quality of its delicate product throughout the winemaking process.

PUMP TECHNOLOGIES IN THE WINEMAKING PROCESS

Today, various pump technologies are used throughout the winemaking and transfer process, and while many offer the applicable features needed to meet the demands of the wine industry, some of those technologies can also come with inefficiencies.

Progressive Cavity

Progressive cavity pumps can be used in the juice-extraction process, but can be susceptible to damage during dry-run conditions. When a pump “runs dry,” it continues to operate even after the wine has been processed in order to clear the lines. As a result, the pump’s components can burn and seize, creating damage to the pump internals. The wine industry, in particular, generally relies on manual-batch production operation that can lend themselves to dry-running conditions. One other possible disadvantage of using progressive cavity pumps in wine applications is that stator/rotor wear can impact the quality and taste of the wine if rubber shavings penetrate the product stream.

Lobe

Lobe pumps are commonly used in wine applications due to their portability and low shear. One concern, however, is the presence of a rotary seal, which increases the possibility of leaks and contamination. Any presence of a seal increases the likelihood of product leakage, which can lead to expensive downtime and maintenance, along with loss of product. Even one lobe pump advantage—portability—can be a disadvantage as lobe pumps are traditionally heavier in nature, hindering the ease of transfer in wineries. Because of the inefficiencies of lobe (or ECP) pumps at low viscosity, they are also prone to impart shear into the wine and degrade the end product.

Eccentric Disc

Eccentric disc pumps are used in several wineries around the world. Eccentric disc pumps consist of a cylinder and pumping element mounted on an eccentric shaft. As the eccentric shaft is rotated, the pumping element forms chambers within the cylinder, which increase in size at the intake port, drawing fluid into the pumping chamber. The fluid is transported to the discharge port where the pumping chamber size is decreased. This action squeezes the fluid out into the discharge piping. Eccentric disc pumps are seal-less, self-priming and can run dry, while also providing shear-sensitivity and gentle transfer of products. They are exceptional at clearing tanks and piping. In wineries, they are ideal for transfer from storage tanks to tangential filters, or to bottling tanks.

The operational advantages of using AODD pumps in winemaking processes are many, including easy to clean and maintain; gentle handling of delicate fluids; capable of moving large volumes; seal-less design; and portability.

Centrifugal

Centrifugal pumps are commonly used in large wineries for tank-to-tank wine transfers although, due to the absence of self-priming capabilities, they are most effective if they are placed below the level of the tank outlet. Another concern with centrifugal pumps is that they tend to homogenize air in wine and trap the oxygen, producing oxidation that adversely affects the taste of the wine.

Peristaltic (Hose)

Peristaltic pumps boast some advantages in wine applications as they can effectively transfer the most delicate or abrasive fluids, fluids containing solids, can run dry and handle higher capacities. Peristaltic pumps are also self-priming, have high suction-lift capabilities and can run in forward or reverse. Unfortunately, these positives can be outweighed by a few operational negatives: their mode of operation creates pulsation within the transferred product; hoses must be changed regularly, which increases downtime; and the rubber hose can shed or spall, which can lead to product contamination.

Diaphragm

The pump technology that has been gaining greater acceptance in wineries around the world is found in diaphragm pumps. Diaphragm pumps, which account for approximately 25 percent of the pumps used in the wine industry worldwide, are easy to clean and maintain and offer the gentle handling required in winemaking and transfer. Diaphragm pumps can also move large volumes of fluid and can be set up to automatically stop when pumping against a closed valve due to the back pressure of the hose. Diaphragm pumps are portable and have no seals, which allows them to keep outside air from compromising the integrity of the wine.

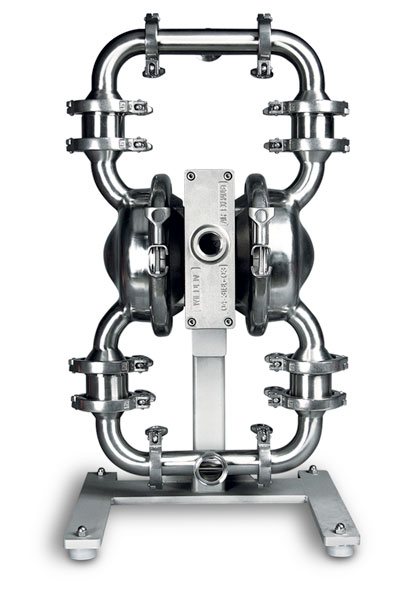

Wilden® PX8 Saniflo™ Hygienic Series™ AODD Pump

THE AODD ADVANTAGE

Transferring must to fermentation tanks requires a pump that can meet the flow and head requirements while handling the larger solids without damaging the product. The ideal pump for this application is an air-operated double-diaphragm (AODD) pump, which can be used throughout the winemaking process, including:

- Pumpover: This is the process of pumping the juice at the bottom of the fermentation tank over the top layer of grape skins and allowing it to seep through. This circulation process occurs frequently throughout the day, and for extended periods of time.

- Transfer: After fermentation, the wine is transferred to a new tank via cart-mounted pumps.

- Press: Any remaining juice and leftover skins and solids are pumped to a press. This pressed wine is then capable of being added to the free-run wine or used for blending.

AODD pumps provide the operational reliability and efficiency that both small and large winemakers demand. For example, the Saniflo™ Hygienic Series™ (HS) AODD Pump by Wilden®, part of Pump Solutions Group (PSG®) is an ideal choice for general transfer, pumpover processes, filter feed and lees (deposits of dead or residual yeast) handling. The Saniflo HS Series pump features a seal-less design that minimizes air incorporation and oxidation, while its low-shear design ensures that the quality of the product is not compromised. Its gentle handling also reduces the release of seed tannins in the must.

Wilden® Full Stroke Integral Piston Diaphragm (FSIPD)

SANIFLO HS SERIES PUMPS UP CLOSE

Wilden’s Saniflo HS Series AODD pumps are also portable and comparably lightweight, and feature dry-run and deadhead capabilities that help ensure the safety of the pump. These pumps are also lubrication-free and offer strong suction. Additionally, they are available in ½ inch (13 millimeter) to 3 inch (76 millimeter) sizes. They feature maximum pressures to 250 psig (17 bar) and flow rates to 223 gallons per minute (884 liters per minute). Saniflo Hygienic Series pumps also utilize standard FDA-compliant materials, and when properly equipped, carry the 3A Symbol based on standard 44-03. This standard validates sound hygienic design and EHEDG Doc. 2 and 8, which certifies cleanability.

Additionally, the Saniflo pumps are able to be outfitted with Wilden’s new Full Stroke Internal Piston Diaphragm (FSIPD). The FSIPDs are constructed of food-grade Wil-Flex™ (Santoprene™) and, unlike competitive models, do not incorporate an outer metal plate that requires the pump to be cleaned manually. Instead, the metal plate is integral to the flexing material, resulting in a diaphragm that features a large integral piston and longer rubber/TPE shaft that enables it to maintain the same stroke length as traditional diaphragms. This means increased product displacement per stroke, improved suction lift, greater flow rates and higher operating efficiencies, all of which serve to optimize the winemaking process.

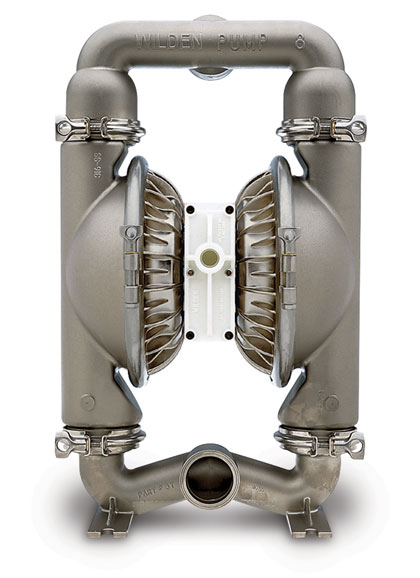

Wilden® PX15 Original™ Series AODD Pump

CONCLUSION

According to the Wine Institute, California accounts for 90 percent of U.S. wine exports, valued at $1.43 billion. The European Union’s twenty-seven member countries are the largest importer of California-produced wines at $485 million, followed by Canada at $434 million. California wines play a prominent role in the global wine industry, and those California winemakers depend on the best pumping technology to help them produce the highest quality wines enjoyed the world over.

Just as many wine enthusiasts trust their palates to California vineyards, winemakers around the world trust their pumping needs to California pumps—specifically, AODD pumps manufactured in Grand Terrace, California. From vine to wine, everything tastes sweeter with Wilden. ■

_________________________________________________________________________

ABOUT THE AUTHOR

David Kirk is the hygienic market manager, Americas for Wilden® and Pump Solutions Group (PSG®), Oakbrook Terrace, IL, USA. He can be reached at 707.484.9023 or david.kirk@psgdover.com. Wilden is the leading manufacturer of AODD pumps and part of PSG, which is comprised of several leading pump brands such as Abaque®, Almatec®, Blackmer®, Ebsray, Finder, Griswold™, Maag, Mouvex®, Neptune™, Quattroflow™, and Wilden®. For more information, visit Wilden at www.wildenpump.com and PSG at www.psgdover.com.

_________________________________________________________________________

MODERN PUMPING TODAY, October 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()