On a quiet, leafy street on the outskirts of the Adelaide CBD sits APC Technology. The peaceful exterior and Managing Director Scott Begbie’s laid-back attitude don’t give much away.

“We have ‘MythBusters’ moments in the car park, making things like explosion proof PCs for oil rigs. We were pressure testing a particular unit – we blew the back off it and stripped 16 hefty bolts right out of the back,” Begbie says. “A lot of the time we just try and break something. The neighbors don’t really know what we do.”

APC Technology specializes in making components rugged enough for extreme conditions and industries. Whether it’s for the bottom of a mine, a surveillance plane’s cockpit, or the interior of a tank, the job is to make it work.

Long-term, experienced staff helps APC increase efficiency.

HISTORY IN PROGRESS

This year, APC Technology are marking thirty years in business, a testament to their ability to quickly adapt and iterate, the esteem their customers hold them in, and the staying power of their workforce. Begbie points out the various facets of APC’s workshop. There are people designing, assembling and testing components. Consoles for Australia’s Air Warfare Destroyer project lie hidden under a tarp.

“We’re testing in a range of conditions. Things are getting submerged; they’re operating at 185 degrees Fahrenheit (85 degrees Celsius); they’re freezing. We’ll freeze them and then put them in the ovens to thermal shock them. It’s generally hardcore stuff,” Begbie explains.

There are stacks of equipment and components, testing chambers for humidity, temperature, shock resistance, and more. It’s not far removed from a mad scientist’s laboratory—just better organized. APC started out in the mid-80s making rugged things like control panels and switches for industrial automation.

“They were in harsh environments where computers wouldn’t normally work. The industries couldn’t find anything that would. So we thought we’ll go and make our own computers,” Begbie says.

RUGGEDIZED COMPONENTS

Before long, the defense industry caught on to the fact that they didn’t need to buy expensive, custom built systems – they could just up spec industrial components.

“APC were one of the first to make ruggedized military systems from commercial equipment,” he says. “It’s easier to go in to the industrial arena with a defence pedigree behind you. We did it for a tank, what’s so hard about a train? It gives you that credibility.”

When Begbie first joined the APC Technology, military and defense contracts made up the majority of work. Now it sits at around a quarter of their total workload, though the total turnover of the business has greatly increased.

“As a percentage it’s not huge—but in dollar terms it’s probably twice what it was before, along with mining, rail, oil and gas, farming, food, pharmaceutical and all of those industries too.”

INCREASED DEMAND, EXPANDED REACH

The spread of industries ensures that APC has a steady stream of business no matter what happens outside.

“At any given time at least three or four of those are pretty buoyant. This year there’s been a lot of defence work come in. The dairy guys are having a record year. We’ve landed a significant domestic rail contract. The good thing is we’ve more than doubled turnover and we’ve only got one extra person,” Begbie says.

APC’s advantage is their flexibility. They’re small and can adapt their workflow to quickly cater to customers’ needs.

“One business we worked with in the United States—we generated a prototype for them faster than they approved the minutes of the meeting about building that prototype,” Begbie says. “That’s what happens when you’re a big company burdened by process.”

Begbie attributes a lot of their success to the fact that the customer determines the timing of the project.

THE ROLE OF 3D PRINTING

As the technologies that they ruggedize change, so do the company’s processes. That introduces plenty of challenges—but it makes some things easier.

“Display technologies change. Everything is faster, everything is smaller. Faster motherboards have different electromagnetic vulnerabilities and frequency ranges,” Begbie explains. “But along comes a 3D printer and suddenly it’s easier to show the customer what they’re going to get. We had one customer sit here wanting the door of one of their units to be a little different.

“I excused myself, came back a little later and finished the meeting. One of our CAD guys came in with a new 3D printed door, asking if that was what the customer wanted. He just said, ‘I’ll take twenty-five of them!’”

That technology has also helped their prototyping work. It typically takes APC only a day or two to design a unit, but the metalwork can take several weeks. Often they’ll send a 3D printed prototype ahead of time to ensure that the mounting, wiring and placement works as promised.

“3D printing has been pretty good for us,” Begbie admits.

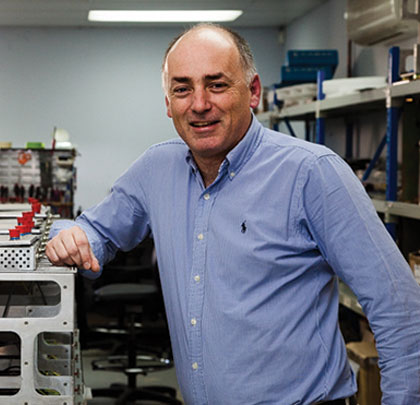

In APC’s workshop, skilled technicians design, assemble, and test components for a range of applications.

INGENUITY AT WORK

Their staffing practice has also helped them increase their efficiencies by a significant amount—as mentioned, they’ve doubled their turnover with only one extra set of hands.

“When we need people, we always attempt to promote people internally. So the latest CAD guy worked in manufacturing. He had a passion for CAD. He was good at it. Now, when he designs something, he knows how to think from a manufacturing perspective—so that’s inherent in the design now.”

An external review of the company pointed out a very low turnover rate. Begbie says it was around two years since the last person left; before that it was another two years. Their longest serving staff have over twenty years with the company.

“People are here and they’re here for a while. We try and have some fun and two days are never the same.”

Managing director of APC Technology, Scott Begbie.

GLOBAL EXPERIENCE

Begbie’s previous work at BAE is probably what keeps APC Technology fresh for him—instead of working for years on one project, they service a wild variety of jobs.

“We’ve got a dairy customer, he buys 500 units a year. That’s one of the most challenging things. For some reason dairy keeps breaking things. People generally come to us for one or two units. The P3 Orion job was twenty-two, around that. We’re making drive through units for fish and chip shops. We have computers in battle tanks, trying to survive the shock pulse of the main guns,” Begbie says, “not even a human can survive that. When I first came on, it was submarines. We had that turned around in eight weeks – designed, made, certified and installed.”

APC Technology recently brought on Rear Admiral Kevin Scarce AC, CSC, RANR—the previous governor of South Australia and head of the Defense Materiel Organization (DMO)—on board to help them navigate complex projects.

The DMO is responsible for the entire Australian Defense Force’s military platforms and equipment. The next big project on the horizon is a bid at the Land 400 in partnership with Singapore company ST Kinetics, an arm of Singapore Technologies Engineering Ltd.

“That’s a company transforming project—obviously if you win it. We’re playing against some seriously big companies. They’ll have one department that’s bigger than our company, just set aside for this project.”

They’re relying on ST Kinetics to prime the project. APC will act as their Australian branch in many respects.

“We treat Singapore as essentially just another state. They’ll call a meeting and we’ll just go. If it’s tomorrow, we’ll fly tomorrow. It freaks them out a bit. It’s often hard for our clients to come to terms with the flexibility you can get,” Begbie explains.

“It’s a seven hour plane ride, so you can get to Singapore faster than a remote Australian mine site. So they’re concerned as to how we’ll support them – well, if we can support a mine site, we can certainly support you in a capital city with direct flights!”

That is how APC have stayed in the game for thirty years; work smarter, get it done faster, and build it to your customer’s exacting standards.

“If you’re the customer, we endeavor to get really close to you,” Begbie says. “If you need something, someone will be there.” ■

For More Information

APC Technology is a leading designer, manufacturer, and supporter of computer/control and innovative sub-system technology packages for a diverse range of demanding operational environments. For more information, visit www.apctechnology.com.au.

MODERN PUMPING TODAY, January 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!