Every waterjet shop wants to produce their parts at the lowest possible cost. To achieve this objective, nothing is more important than a correctly sized waterjet pump. But selecting the perfect pump to power your waterjet system can be a mind-boggling task. There are so many choices and considerations to make. Do I need a hydraulic intensifier pump or can I get by with a cheaper direct drive pump? How much pressure do I need? How much horsepower? The list goes on.

WHAT’S YOUR APPLICATION?

Waterjet industry veterans Bradley Schwartz and Jeff Schibley of Jet Edge have a combined experience of more than fifty years in the waterjet industry. Minnesota-based Jet Edge has been manufacturing waterjet systems since 1984 and offers a wide range of waterjet pumps. Picking the perfect pump always begins by identifying your specific application, Schibley notes. This will help your waterjet pump manufacturer determine your pressure, horsepower, flow rate, and other requirements.

“We’ll ask you several questions,” he continues. “What are you cutting? How fast do we need to cut the product? Can we make the customer’s throughput requirements with a single nozzle? Does the application require multiple nozzles? Can the cutting application be performed with straight water? Does the application require the addition of abrasive?”

A reputable waterjet manufacturer will always help their customer determine the most efficient and cost-effective pump for their application, Schwartz adds.

“If I’m cutting nothing but very soft tile that cuts fine at 36,000 psi, I might as well put in a 36,000 psi pump and cut with six heads,” he adds. “But if I’m cutting 3 to 6-inch (7.62 to 15.24 centimeters) steel all day long, I’ll need a 60,000 psi pump. If I want to use 50 horsepower per head and I want to use two heads, that pump will need to be 100 horsepower.”

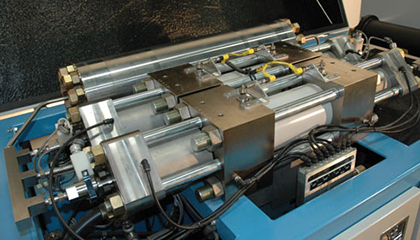

A look inside a 100 horsepower Jet Edge X-Stream intensifier pump. All Jet Edge pumps feature a reliable a tie-rod design.

THE ALL IMPORTANT TEST CUT

Most waterjet manufacturers offer free test cuts to help their customers determine the appropriate pump and motion system set up for their application.

During the test cut, the manufacturer will run a series of tests to determine the most efficient cutting pressure, horsepower, and speed to achieve the customer’s throughput requirements.

“During the test, we determine if we can process the customer’s material with straight water or if we need to add abrasive,” Schibley explains. “We also determine how much pressure and what orifice size and how many cutting heads are required to make their throughput requirements. If the application requires abrasive, we will determine how much abrasive is required and the most efficient orifice/nozzle combination. Once we have determined these factors, we can size the pump and flow rate.”

Schwartz noted that the test cut will help the customer select the most cost-effective pump for their application and also will arm them with cutting data that will help them keep their operating costs as low as possible by running their system at the most cost-efficient pressure, using the least amount of abrasive necessary and running the appropriate number of cutting heads to achieve their desired throughput.

“As an example, when I’m cutting upwards of a ¼-inch (6.35 millimeters) material, I would use two heads and I would use 25 horsepower per head to cut it because I’m not going to be cutting that much slower than I would at 50 horsepower, but I will use half the abrasive and I am using two heads so I will double my production,” Schwartz says. “When I go up to 2-inch (5.08 centimeters) thick material, I will go to 50 horsepower per head. It only takes me a minute to change the orifice and nozzle to bring my horsepower up and down. That is how you change the horsepower, with different orifice sizes. At 60,000 psi, 25 horsepower uses a 0.010 inch (0.25 millimeters) orifice. When you go to 50 horsepower, you use a 0.015 inch (0.38 millimeters) orifice.”

Of course, when all is said and done, the pump must be within a customer’s budget, and sometimes that means scaling back a bit on horsepower or pressure and accepting a higher cost per part, Schibley notes.

“We have to take into consideration the customer’s financial considerations,” he says. “Just because a 60,000 psi 200 horsepower pump operating four 0.015 or 0.045 inch (0.38 or 1.14 millimeters) orifice/nozzle combinations makes the lowest cost cut, doesn’t mean it is the best pump for the customer if it doesn’t meet his financial requirements.”

The 80 horsepower, 60,000 psi Jet Edge iP60-80DS pump is useful for oilfield & other mobile site work.

INTENSIFIER VS. DIRECT DRIVE

There are two basic types of waterjet pumps, direct drive pumps (also known as positive displacement or crank pumps) and hydraulic intensifier pumps. A direct drive pump uses a crank to drive the pump’s plunger, while an intensifier uses a hydraulic cylinder to drive the plunger. Direct drive pumps cost less than hydraulic pumps up front, but require much more maintenance. They are a good economical alternative for shops that only require an entry level system for low-volume cutting. Intensifier pumps are recommended for shops that need to process higher volumes of material and thicker materials.

“Jet Edge has always been a proponent of intensifier pumps because they are easier to maintain and have lower maintenance costs and less downtime,” Schwartz notes. “We do offer direct drive pumps, however, because sometimes that is all a shop has budget for and it may be all they need.”

EXTREME CUTTING PRESSURES

In the last few years, waterjet pump manufacturers have begun offering pumps with operating pressures exceeding 90,000 psi. These extreme pressure pumps cost more up front than 60,000 psi pumps, but can greatly increase productivity and can lower operating costs as much as 40 percent by cutting faster and using less electricity, water, and garnet.

“Where extreme pressure pumps really come in handy is when you have a single cutting head and you want to double production,” Schwartz notes. “Very easily I can do that with 90,000 psi pump as compared with 60,000 psi. It also has the advantage of using less abrasive, and abrasive is your main cost per hour at up to 40 cents a pound. A typical abrasive waterjet system uses a half pound to a pound and a half per head a minute so you can see how the savings can add up quickly if you’re using 40 percent less abrasive at 90,000 psi.”

In applications requiring three or four cutting heads, Schwartz recommends sticking with a 150 to 200 horsepower 60,000 psi pump for its higher flow rate.

“A 150 or 200 horsepower 60,000 psi pump has a higher flow rate than a 100 horsepower 90,000psi pump, and it is easier to divide that up to four heads,” he explains. To determine if extreme pressure cutting is right for your application, ask your waterjet manufacturer for a test cut.

The 150 horsepower, 60,000 psi Jet Edge iP60-150 is one of Jet Edge’s most popular pumps for high volume shops that require multiple cutting heads. It produces up to 3 gallons per minute (11.4 liters per minute) of ultra-high pressure.

WHERE TO GO FOR MORE INFORMATION

As you would with any capital purchase, its best to arm yourself with as much information as you can before you buy a waterjet system or pump. Excellent educational information is available on manufacturer and trade industry websites. Sit in on manufacturers’ webinars, visit their manufacturing facilities, and check out their machines at industry trade shows. Ask for referrals and references and see if your manufacturer can arrange a tour at one of their existing customer’s shops.

But whatever you do, do not skip the test cut! The test cut will help you pick the perfect pump for your system and it will help you determine the most cost effective and productive set up for your application. Having the experienced waterjet manufacturer do this for you upfront instead of figuring it out on your own will save you time and money.

_______________________________________________________________________

ABOUT THE AUTHOR

Nancy Lauseng is marketing manager for Jet Edge, a leading manufacturer of ultra-high pressure waterjet technology. For more information about Jet Edge, visit www.jetedge.com or call 800.JET.EDGE or 763.497.8700.

_______________________________________________________________________

MODERN PUMPING TODAY, April 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!