The transition from independent septic systems to a centralized low-pressure sewer (LPS) collection system has economic, environmental and altruistic advantages to communities like the Town of Jerusalem, New York.

A decade after the installation was complete, the Town of Jerusalem and E/One decided to embark on a unique study: Parts Two and Three of this article provide a ten-year (2003-2013) review of Operation and Maintenance (O&M) data and a hydraulic performance analysis comparing expected design flows to quantitatively measured flows for the 265-unit septic tank replacement project.

Three key conclusions regarding this LPS are evident from the data: the system is reliable and cost-effective, hydraulically flexible and improves quality of life.

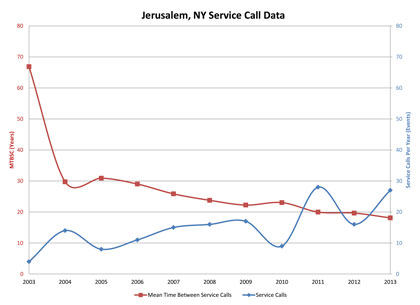

Figure 1: Service calls and the MTBSC for the ten-year period under analysis.

FINDING THE RIGHT MEASUREMENTS

Perhaps the self-evaluation could predict future performance by revisiting the past. “In business, the idea of measuring what you are doing, picking the measurements that count like customer satisfaction and performance … you thrive on that,” Bill Gates once said.

Operation and maintenance records and invoices from the Town of Jerusalem files were analyzed for the period from January 2003 through December 2013. Office and maintenance personnel were interviewed regarding their experiences with the project.

The project team of Clough, Harbour & Associates LLP (CHA); Siewert Equipment Company; the Town of Jerusalem; Environment One Corporation (E/One); and local plumbing company Dean Roberts Plumbing and Heating established a procedure for addressing service calls and system maintenance. All parties were factory trained and certified by E/One field service personnel.

Simple removal and installation of the pump for service is inherent to the design of the E/One grinder pump. The station’s components are accessible by removing just three bolts on the access lid. Homeowners experience minimum downtime and a maintenance crew can repair and test the damaged core in the shop.

Service calls were initially routed to Town of Jerusalem maintenance personnel. An initial field assessment was performed. If the pump required repair, Dean Roberts Plumbing and Heating was contacted. A representative removed the pump from the grinder pump station, installed a replacement pump, transported the pump requiring service back to their service shop, repaired it and readied it for return to use.

Service records show a “Standard Repair” was often performed consisting of pump stator, pressure switch and start contactor replacement.

RELIABILITY AND MEAN TIME BETWEEN SERVICE CALLS

Mean time between service calls (MTBSC) was calculated to be approximately twenty-eight years. During the 10-year period, 165 calls were recorded on 274 pumps.

Only 70 of the 274 pumps on the project experienced a service call. However, 27 of these 70 pumps experienced two or more service calls. These “repeat calls” accounted for 71 of the 127 calls or 56-percent of the calls.

The root causes of these calls were traced to the following and were quickly corrected. Many were attributed to excessive disposal of cooking grease into the wastewater stream by several homeowners and root penetration and obstruction of the inlet line between homes and grinder pump stations.

A spike in service calls was experienced in 2011 due to a prolonged power outage.

Power was out for an extended period of time and homeowners inadvertently continued to use water. This resulted in several flooded stations and a variety of flood related call outs.

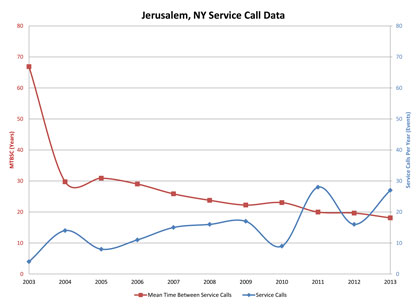

Figure 2: Annual maintenance cost per pump for the ten-year period under analysis.

OPERATION & MAINTENANCE (O&M) COSTS

Figure 2 and the interviews reveal several observations: During the ten-year period, the O&M cost per pump was approximately $37 per pump per year (excluding power). This is consistent with many other E/One LPS installations which typically report O&M costs ranging from $30 to $50 per pump per year.

Initial O&M costs were very low from 2003 through early 2005 due to the focus the project team placed on installation training and inspection of installations.

Costs increased in 2005 due to a significant number of relatively expensive pump motor repairs. This problem was traced to a manufacturer’s defect in a push-to-run switch used on the grinder pump alarm panel.

The switch was prone to shorting out in the closed position. This caused the grinder pump to run continuously resulting in excessive wear on the entire pump. Occasionally the pump motor would become damaged due to excessive heat and require replacement.

The practice of typically performing a “standard repair” on pumps mentioned in the maintenance procedure section above contributes to slightly elevated O&M costs. This practice may lead to the replacement of components that still have several years of useful life remaining.

However, since all pumps are owned by the Town of Jerusalem, it is understandable that they would invest in upgrading a pump when the opportunity presents itself. This practice slightly increases the O&M cost per pump per year. However, it also lengthens the MTBSC at minimal cost.

A LOOK AHEAD:

Part Three of this article provides a ten-year (2003-2013) review of hydraulic performance analysis comparing expected design flows to quantitatively measured flows for the 265-unit septic tank replacement project. ■

About the Author

Wayne Ackart, P.E. is town engineer for the Town of Jerusalem. Clark A. Henry is director of engineering at Environment One. He can be reached at chenry@eone.com. Michael Crowley is LPS system designer at Environment One. For more information on Environment One Corporation’s full line of grinder pumps and LPS solutions, visit www.eone.com or call 518.346.6161.

MODERN PUMPING TODAY, September 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!