In last month’s introduction to this case study, U.S. Water implemented a water treatment program to minimize issues in off-line condensers and established a microbiological and biofilm control program to help the University of Texas meet its goal of introducing a reclaimed water program to its campus.

Featured Image: Cooling towers at work on the University of Texas campus.

Above: U.S. Water’s DATS deposition monitor continuously measures heat transfer efficiency in the cooling system.

PROGRAM MONITORING

Installation of up-to-date feed and control equipment made it possible to constantly measure and control all treatment parameters. Information was outputted directly to the U.S. Water web-based data management program providing access to real time conditions for both university and U.S. Water personnel.

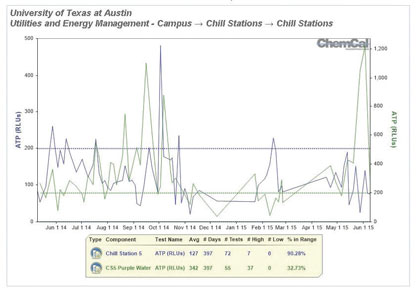

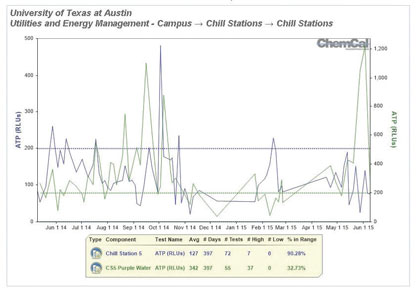

Corrosion rates (see figure 2) were continuously monitored using LPR style corrosion sensors. A DATS deposition monitor continuously measured heat transfer efficiency. Heat exchanger surface temperatures were set at 42 degrees Fahrenheit (5.6 degrees Celsius) over the operating condensers to provide early warning of any possible fouling issues. Microbiological activity was monitored by plating bacteria cultures and with ATP (Adenosine TriPhosphate) testing (see figure 3). Regular field tests measured conductivity, pH, ATP, iron, copper, phosphate, and corrosion inhibitor concentrations. Additionally, once per quarter, samples were sent to the U.S. Water analytical laboratory, in order to verify field results with more extensive testing.

Figure 2

Figure 3

PERFORMANCE SUMMARY

The results pointed to a program that provided solid corrosion, deposition and microbiological control. There have been no deposition or corrosion related issues after almost two years in Chiller Station 5. Biomonitoring showed less than 1000 cfu/ml total aerobic bacteria counts with less than 10 cfu/ml of sulfate reducing bacterial (SRB) present in the system. Based on this multiyear study, the University of Texas at Austin is building a new 15,000-ton chilling station which will use reclaim water for cooling tower make-up.

CONCLUSIONS

Municipal reclaim water can successfully replace potable water in district energy/power applications. Actions to take include analyzing the reclaim water over extended time frames to capture the diurnal and seasonal variability of the reclaimed water quality, identifying the critical parameters that are unique to reclaim water such as chlorides, phosphate, ammonia, total organic carbon, and total suspended solids and selecting options to address or mitigate the problems that each may cause. These options may include changes in system design, materials of construction, chemical treatment, or system operation and control.

The University of Texas at Austin employed all of these in their solution producing excellent results. ◆

Gary Engstrom is technical manager for U.S. Water. Jim Lukanich is technical resource for U.S. Water. U.S. Water, a subsidiary of ALLETE, Inc., provides options for environmentally friendly, safe, and cost-effective water management. As experts in water, they use their in depth industry knowledge and experience to enhance system reliability, efficiency, and profitability. For more information, visit www.uswaterservices.com.

____________________________________________

MODERN PUMPING TODAY, September 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()