Electrical energy represents a substantial portion of industrial operating expenses. It is an unavoidable cost of doing business that all too often seems resistant to control or moderation. However, PRUFTECHNIK, the inventor of laser shaft alignment, provides a solution. Drawing on over forty years of experience in industrial alignment, PRUFTECHNIK demonstrates how precision alignment brings down energy costs.

The idea is simple. Reduced energy consumption means reduced energy costs. Because precision alignment saves energy, it saves money. Understanding what we mean by precision alignment and why precision is important reveals the reasons why.

WASTING ENERGY HURTS THE BOTTOM LINE

Energy costs can represent a major part of the expenses associated with manufacturing equipment. With heavy machinery, energy costs often dwarf purchase price and maintenance charges. In fact, energy consumption may approach 90 percent of the lifetime cost of owning and operating in-line equipment. Thus, reducing energy consumption leaps to the forefront of any effort to reduce costs in industrial operations.

The savings that can accrue from precision alignment are often overlooked. While energy represents hundreds of thousands of dollars of operating expenses, a significant portion of that expenditure is pure waste. Misalignment of coupled machines squanders valuable energy dollars. Precision alignment of machine shafts have been demonstrated to cut energy costs by as much as 10 percent. Moreover, correctable misalignment conditions also shorten the service life of machines, increase machine failure, cause work stoppages and plant slowdowns, and reduce product quality. Misalignment is expensive and unnecessary. Precision alignment of coupled machines reduces the mean time between failures and dramatically reduces energy consumption. A precision laser alignment program can save thousands of dollars over the life of a single machine.

WHAT DO WE MEAN BY PRECISION ALIGNMENT?

“Alignment” describes the positioning of two or more machines so that they can effectively transfer power from one to another. With rotating equipment, such as a motor and pump combination for example, machines are set up so that their shafts are collinear. In other words, they are positioned such that during operation their axes of rotation turn precisely together along a single unified line. Accurate positioning is important because the more precisely the machines are aligned, the more efficiently the rotational power is transferred.

Alignment is defined by two important conditions: gap, also known as angularity, and offset. These conditions describe the relationship between the center axes of machine shafts when machines are coupled together. Misalignment occurs when the coupled shafts are positioned so that their gaps or offsets are outside acceptable limits.

Proper alignment requires an understanding of more than just the static positioning of machines. A number of factors influence alignment and create differences between a machine that is running and a machine that is at rest or “cold”. Important factors to consider include:

- catenary bows (normal sagging due to the weight of the shafts)

- operational conditions such as the thermal expansion of machines as they run

- the influence of torque

- the stability of machine feet

- the pressure of attached piping or other equipment

- play or looseness in the bearings

- operational RPMs (revolutions per minute)

All must be accounted for, and alignment must be adjusted accordingly. As a result, the operational or “live” alignment values of a machine under normal operating conditions may be different from those of a static or cold one.

Precision alignment means reducing the measured gaps and offsets to within limits that provide for the most efficient power transfer from shaft to shaft when a machine is operating.

Precision alignment will reduce shaft loads and destructive vibrations, limit overheating, slow wear on bearings, seals, and shafts, reduce breakdowns and unscheduled maintenance, improve product quality, and significantly save energy.

Top Left: Vertical offset, Top Right: Vertical angularity

Bottom Left: Horizontal offset, Bottom Right: Horizontal angularity

WHY IS PRECISION IMPORTANT?

A variety of factors combine to determine acceptable tolerances for shaft alignment. The style of coupling used, the equipment power rating, the expected revolutions per minute, the length of any spacer couplings, and the service life of the machines all influence the limits that define appropriate alignment. Frequently the difference between acceptable and out of tolerance alignment is a matter of thousandths of an inch. The difference between 2 and 2.5 inches may not sound big, but these seemingly small misalignment values have an outsized impact on the efficient and energy saving operation of a machine.

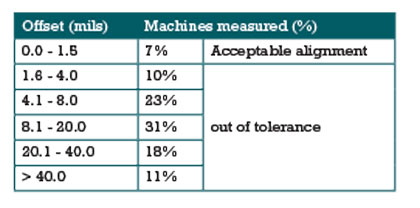

Despite its importance, however, misalignment of coupled machines is common. Studies show that more than 90 percent of industrial equipment is misaligned. One survey by a leading rotating equipment service organization revealed that the vast majority of industrial machines are operating outside of appropriate alignment tolerances. Of 160 coupled machines running at 3600 rpm and randomly chosen for testing, only 7 percent were aligned within generally accepted industry limits.

There are a number of reasons why coupled machines might be misaligned. Before PRUFTECHNIK introduced its innovative precision laser alignment systems, machine alignment could be haphazard at best. Historically machines were often aligned by eye or by resting a straightedge along the top of the couplings. This kind of coupling alignment was inadequate because it did not measure alignment at the point of power transfer on the shafts but instead at the couplings which were often only roughly machined. Sometimes alignment was attempted using a Vernier or feeler gauge, but again, this method would align only the couplings and not the rotating shafts. Precision alignment cannot be achieved this way. Moreover, these methods rely on the powers of the human eye. As wonderful as they are, human eyes simply do not possess the resolution necessary for precision alignment of modern machinery with their narrow alignment tolerances.

A LOOK AHEAD

Common attempts at more accurate alignment often produce poor results. In next month’s conclusion to this article, we’ll take a closer look at the comparative strengths and weaknesses of different measurement techniques, provide some of the benefits of precision laser alignment systems, and dive deep into how precision alignment saves energy. ◆

With many years of experience in industries, processes, and applications PRUFTECHNIK offers innovative and customer-oriented solutions for maintenance and quality assurance. For more information, email usa@pruftechnik.com or visit www.pruftechnik.com.

_____________________________________

MODERN PUMPING TODAY, May 2017

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()