What happens when you mix the sanitary flow from a large office and medical complex with flushable wipes? The answer is a nightmare for wastewater equipment and maintenance personnel.

The problem has been well documented with news, video, and newspaper coverage from across the United States. According to one clean water agency official, the public is being duped by manufacturers into believing that “flushable” wipes are safe for use in sewer and septic systems. Flushing wipes down the toilet has become a major problem for wastewater facility operators and, the problem has only worsened in recent years.

The problem is both operational and financial.

New York City alone claims that more than $18 million has been spent over the past five years to remedy wipe related problems within their fourteen wastewater treatment plants.

In the Southwest, while visiting a regional reclamation center, a Tucson, Arizona, based news crew documented “white wipes were everywhere.” The operator suspects that the wipes are not biodegrading as fast as the general public is being led to believe. The wipes cake the walls and eventually get stuck in the sewers and clog pumps and pipes. When the blockages occur, there is just one way to clear them, by hand.

In Vancouver, Washington, sewer officials performed their own experiment after spending over $1 million replacing eleven pumps which were routinely clogging due to wipe ingestion. They dyed lots of wipes labeled “flushable” and sent them on a one mile journey through the system. They did not break up.

One of the major producers of flushable wipes claims that the problem is caused by products not meant to be flushed. They explain that flushable wipes, when used as directed, break up after flushing and clear properly maintained toilets, drain lines, sewers, pumps, and septic and municipal treatment systems.

Consumer Reports performed tests that dispute manufacturer’s claims. The magazine ran vortex and mixer tests on several major “flushable” wipe brands that claimed to be safe for sewer and septic systems. After ten minutes of agitation there was no breakdown of the wipes. CR states that the public needs to understand what’s safe to flush and what is not. Their advice, “do not flush flushable wipes.”

Until industry standards for all wipes meet wastewater handling equipment requirements, an informed and responsive public is needed to minimize system downtime and the resulting costs to taxpayers.

But, we all know regardless of warnings and education, the problem will never go away completely. Therefore, waste handling equipment must be upgraded to handle the existence of wipes in the system.

Traditionally, municipal systems employ numerous smaller capacity lift stations to move raw sewage and wastewater from individual sanitary drain lines to main sewers leading to treatment plant intakes. Small lift station pumps are particularly susceptible to clogging since their solids handling capability is limited. These units typically allow passage of soft solids up to one half the suction inlet. They do not easily handle long, stringy materials like wipes, which tend to wrap and bind impellers. The resulting pump clog causes an initial pump failure and quite possibly more consequential motor and system damage.

One pump company has attacked the problem head-on by developing a pump that will shred wipes and other system solids making them more managable for wastewater systems.

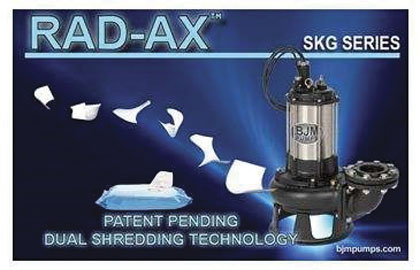

BJM Pumps has long been recognized as leader in submersible, solids handling pumps for industrial and municipal services. BJM Pumps engineers have developed a dual shredding technology which features radial and axial shredding elements. This design obliterates wipes and other hard to handle solids in the waste stream.

The new patent pending, RAD-AX® Shredder pump technology incorporates both radial shredding and axial cutting, which achieves optimum results on hard, to near impossible to pump liquids containing fibrous solids like wet wipes.

The Radial Shredding is achieved by a rotating cutter bar with serrated edges, which traps and shreds solids against the sharp grooves of the radial cutting ring. Wipes and other fibrous debris are efficiently ripped apart. The complimentary Axial Cutting utilizes dual cutting elements operating in tandem to multiply the shearing action. As the material exits the radial shredding area, the axial cutting components shear any remaining pieces using multiple cutting bars. The impeller design expedites the flow and hydraulic performance, preventing wrapping and clogging.

The BJM Pumps Series SKG pump features RAD-AX® shredding elements that are cast in hardened 440C Stainless Steel (Rockwell hardness above 55C) for maximum service life. The patent-pending RAD-AX® design provides unsurpassed solids passage efficiency through its impeller and volute and is available only in the BJM Pumps SKG product line. Available with 2, 3, or 5 horsepower high torque 4-pole motors, these pumps are perfect for smaller waste water stations.

FOR MORE INFORMATION

Brian Mitsch, P.E., is vice president of operations and engineering for BJM Pumps. BJM Pumps is headquartered in Old Saybrook, Connecticut, and has been providing fluid handling solutions for industrial and municipal services since 1983. Over its thirty-three year history, BJM Pumps has grown quickly by supplying world class pumps and accessories, priced competitively, through its global network of stocking distributors.

____________________________________________

MODERN PUMPING TODAY, July 2016

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!