Most of the world’s energy is consumed by industry and buildings. But, according to the International Energy Agency, energy efficiency can deliver 38 percent of the reduction in greenhouse gas emissions required to slow the rate of climate warming.

Ahead of the recent COP21 climate summit in Paris, Danfoss announced new, aggressive energy-efficiency targets for its buildings and operations worldwide—pledging to reduce its energy consumption by 50 percent and accelerate its leadership in the use of energy-saving and climate-friendly technologies.

SEIZING THE OPPORTUNITY

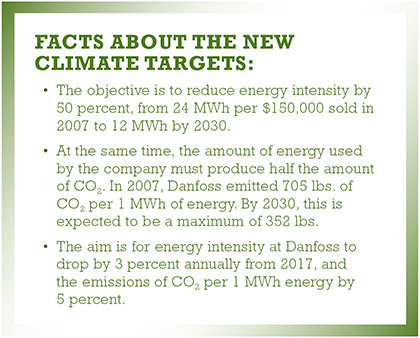

Recognizing the opportunity for its own operations, the company plans to use 50 percent less energy to run its business, and reduce by 50 percent the amount of CO2 emissions resulting from the energy it consumes.

“Worldwide, we deliver some of the most innovative and efficient technologies for saving energy—helping cities and companies to reach their targets,” says Niels B. Christiansen, president and CEO, Danfoss. “Now, we are intensifying our own efforts in the form of a new, ambitious climate strategy, which builds on what we have already done and achieved. We see this as a natural part of leading the way within the climate sector.”

Danfoss has already taken significant measures to help reduce the impact of its buildings and operations, and, thus, is making progress in achieving these new targets. Between 2007 and 2014, the company’s net sales increased by 55 percent, whereas its energy consumption, compared to sales, dropped by 29 percent. Typically, the energy-saving projects being deployed reduce energy consumption required for building operations by 25-30 percent. The savings are primarily obtained through the optimization and control of the buildings’ heating, air-conditioning, and ventilation systems using Danfoss’ own products.

THE KEY TO ENERGY OPTIMIZATION

To build upon this success, Danfoss is now intensifying its efforts to energy-optimize the company’s buildings all over the world. In addition, production line processes will be systematically examined for further energy reductions.

Danfoss is also set to continue introducing renewable energy sources to its portfolio. In 2013, for example, Danfoss installed a solar cell park next to its headquarters in Nordborg, Denmark. It produces electricity equal to the annual consumption of 400 single-family houses and has a total capacity of 2 MW. A 1-MW solar-cell system was also installed at Danfoss’ new campus in Chennai, India, last year, which has received the international LEED Platinum rating, certifying it as an environmentally-friendly and sustainable building complex. A range of Danfoss products is installed to save energy on the campus.

MEETING THE ENERGY 2030 GOAL

In July of this year, John Galyen, president, Danfoss North America, addressed U.S. industrial competiveness through smart manufacturing at the Accelerate Energy Productivity 2030 initiative, a collaborative effort to reach the goal of doubling U.S. energy productivity by 2030. According to the Alliance to Save Energy, achieving the Energy 2030 goal would save $327 billion annually in avoided energy costs, create 1.3 million jobs, reduce imports to a mere 7 percent of overall energy consumption, and lower greenhouse gas emissions to one-third below the level emitted in 2005. Galyen underscored the existence of two paths to increase energy productivity: a short-term and long-term approach.

“In the short term, there are many available, proven—yet under-deployed—technologies that exist today to meet the challenge of doubling energy productivity by 2030 that also have solid ROI,” comments Galyen.

One good example is variable frequency drives. In the United States, an estimated 60-65 percent of all electrical energy is used for motors, where 75 percent of the motors are variable-torque fan, pump, or compressor loads. Only about 3 percent of the total installed base of AC motors are provided with AC drives; however, drive technology is adopted in as many as 30-40 percent of all newly installed motors. Applying VFDs can improve performance and reliability, and reduce energy consumption by 18 percent across the 40 million motors in the U.S. “We need incentives packages to deploy these technologies,” urges Galyen.

“In the long term, we need to be investing in infrastructure: in integrated energy solutions, including combined heat and power, waste incineration, and manufacturing,” Galyen continues.

While not so prevalent in the United States today, combined heat and power is common in other regions of the world, especially in the northern climates. A standard power plant is only 40 percent efficient; 60 percent of the input energy is rejected as “waste heat.” With CHP, however, the overall energy productivity is doubled to 80 percent because the waste heat is captured and used for heating or cooling.

“We have many proven technologies,” Galyen concludes, “but we need to shift behavior and thinking beyond first cost and focus on total lifecycle costs in building and infrastructure investment.”

TAKING A LEADING ROLE

As a leading manufacturer of high-efficiency components and controls for air-conditioning, heating, refrigeration, industrial, and water systems, Danfoss is committed to creating a sustainable energy future, and engineers solutions that help customers reduce their energy footprint with a strong return on investment. Its proven technologies are used around the world to help reduce energy use and carbon emissions in intensive and critical processes, such as cooling of buildings, preserving food supply, optimizing industrial manufacturing, and delivering clean, potable water. ◆

About The Author

Lisa Tryson is director of corporate communications and PR for Danfoss and can be reached at 410.513.1142 or lisatryson@danfoss.com. Danfoss engineers technologies that enable the world of tomorrow to do more with less. We meet the growing need for infrastructure, food supply, energy efficiency, and climate-friendly solutions. Our products and services are used in areas such as refrigeration, air conditioning, heating, motor control, and mobile machinery. We are also active in the field of renewable energy as well as district heating infrastructure for cities and urban communities. Our innovative engineering dates back to 1933 and today Danfoss is a world-leader, employing 24,000 employees and serving customers in more than 100 countries. We are still privately held by the founding family. For more information, visit www.danfoss.com.

____________________________________________

MODERN PUMPING TODAY, December 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()