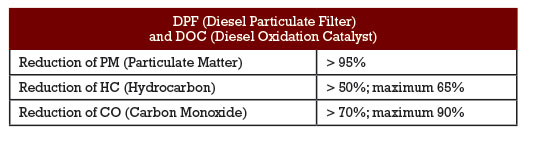

High efficiency pumps are in demand around the world, and for manufacturers, each region presents customers with their own unique needs. BBA Pumps emphasizes a “lowest cost of ownership” philosophy to meet the needs of these customers and continues to strengthen its innovation leadership by announcing the release of the “RF-system” for the PT150 wellpoint dewatering pumps. This after-treatment technology includes a VERT® certified Diesel Particulate Filter (DPF) and Diesel Oxidation Catalyst (DOC). It is specially designed for use with small single-cylinder diesel driven pumpsets with minimal engine load and low combustion temperatures.

VERT®: VERIFICATION OF EMISSION REDUCTION TECHNOLOGIES

The VERT Association is a non-profit organization established in accordance with the laws of Switzerland. An important function of the VERT Association is the testing and certification of diesel particulate filters. The association works worldwide with other relevant authorities in the development of clean air policies and in the design of programs and regulations for combustion engines and engine emissions.

The PT150 high efficiency wellpoint dewatering pump combined with the RF-system provides the most environmentally friendly single-cylinder pumpset worldwide. Nearly twelve months of research and development has led to this result of significant exhaust emissions. This demonstrates a thorough commitment to both durability and environmental stewardship.

NEW EMISSION STANDARDS

By applying the company’s “lowest cost of ownership” philosophy, and combining this with the global environmental demands, BBA Pumps has succeeded in creating a pump that will set the new standard on fewer emissions and significantly lower operational costs.

INCREASED UNIT EFFICIENCY

The conventional V-belt drive is replaced by BBA’s patented Direct Drive Design® and the pump casing has improved hydraulic characteristics. This results in better suction capabilities, more pump flow, and a lower fuel consumption—overall unit efficiency increases by 10 to 14 percent.

DRIVEON® TECHNOLOGY

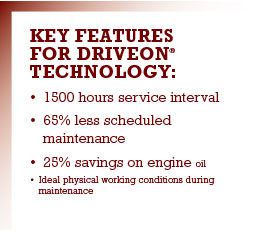

Human engineering was also a key consideration. In fact, the PT150 with DriveOn® technology offers ideal working conditions during maintenance. On top of that, the engine service interval is extended up to 1500 running hours (instead of 500 for the standard engines).

THE KEYS TO REDUCTION

The compact dimensions of the DPF/DOC after treatment system minimizes space requirements in the exhaust system and incorporates a number of features to ease installation and cleaning. These features ensure minimal work for the user due to the inclusion of technical preparations inside the exhaust system and a lockable cover on the outside of the canopy.

ENVIRONMENTAL CARE

Alongside the reduction of emissions and environmental pollution, the Super Silent PT150 is officially certified by an independent organization at a sound level of 48 dB(A) at 32.8 feet (10 meters).

Another environmental-friendly feature is the exhaust module, it is standard completed with a spark arrestor and fully prepared for installation of a Diesel Particulate Filter/Oxidation Catalyst. ◆

Roland Berns is general manager at BBA Pumps. For more than sixty years BBA Pumps has been an advanced and innovative manufacturer of mobile pump systems for various markets, including the rental and well-point drainage markets and civil works.

____________________________________________

MODERN PUMPING TODAY, May 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()