The University of Alabama at Birmingham (UAB) obtained an annual energy savings of $60,000 after awarding a project to Bernhard TME Engineering (TME) to optimize the university’s district chilled water system.

Three existing chilled water plants with 38,100 tons of cooling capacity serve 48 existing buildings on the campus, covering a little more than one square mile. The chilled water system provides cooling for the air conditioning systems in this hot and humid Southeastern U.S. location.

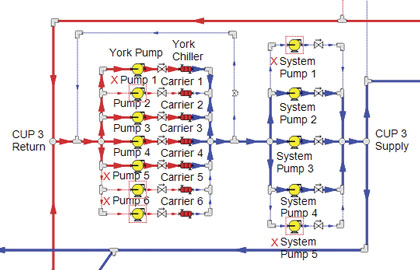

Pumping station diagram

THE CHALLENGE

The university asked TME to (1) model new piping plans and two additional 8,000-ton chilled water plants to support the university’s expected twenty-year growth, and (2) provide strategies for optimizing their current plant operation to be more energy efficient.

Brandon Smith, commissioning technician, and Wei Guo, energy engineer, at TME, used Applied Flow Technology’s pipe flow modeling software, AFT Fathom, to create a hydraulic model of the existing district chilled water system.

The plant operates off of a fixed differential pressure set point based on the combination of dry bulb and wet bulb outside air temperature. The differential pressure setpoint had been proven to satisfy the chilled water demand of the buildings after years of experience but was not necessarily the most efficient way to do so.

Click here to download the UAB chilled water piping diagram.

Smith and Guo were able to run simulations with of the chilled water plants’ pumps in several different arrangements in order to determine the most efficient way to run the plants.

A major step to reduce the plant differential pressure set points and reduce overall energy cost was to determine the most hydraulically remote building and add booster pumps to that building. Due to the very large and multi-branched piping layout of the campus, the most hydraulically remote building was not able to be guessed at based on building size or location.

THE SOLUTION

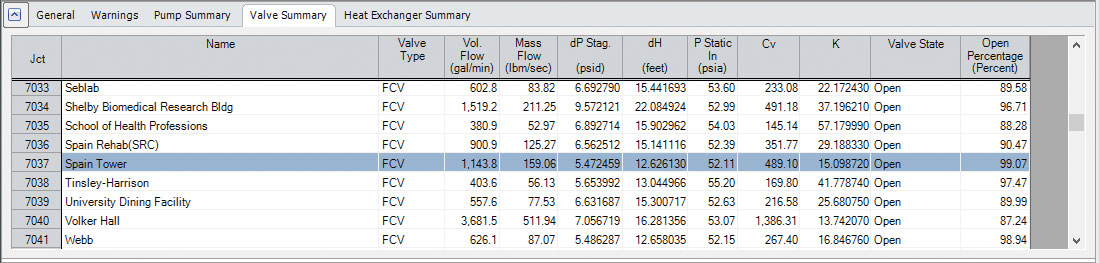

With AFT Fathom, Smith and Guo were able to determine the most hydraulically remote building based on which building’s control valve was most open. Knowing which buildings were most critical allowed TME to add booster pumps and run several different scenarios to determine the best operating condition for the plant.

Click here to download the Full Model Overlay

“We were very impressed by how quickly AFT Fathom is able to process and calculate solutions for such a large piping network,” says Smith. “Without the speed of AFT Fathom, this type of modeling project would not have been economically feasible for the university to invest in.”

After running the analysis, Smith and Guo determined one building was causing all of the plants to run at differential pressures much higher than necessary. By adding a booster pump to that building, the campus is able to obtain an annual savings of $60,000 a year.

Smith and Guo also utilized AFT Fathom to assist with designing the proper pipe sizes for the university’s future growth. Additionally, the model is now set up to help make future design decisions such as chilled water plant locations and building booster pump locations, and also assist in determining the best sequence of operations for the plant’s optimal savings.

Valve summary

Smith and Guo submitted the UAB project to AFT’s Platinum Pipe Award Contest and received the 2016 award for the Operational Benefits and Sustainability category. The award recognizes excellence in piping and ducting system modeling using AFT software.

“The application of AFT’s system modeling software at UAB continues to demonstrate the value of system modeling and the power and versatility of our software products,” says AFT President Trey Walters, P.E. “There is much work to be done to improve the energy efficiency of installed pumping systems and to change the paradigm of how pumping systems are initially designed to reduce their environmental footprint. This application is an important step in that direction.” ◆

Chelsea Woodward is the public relations and social media coordinator at Applied Flow Technology in Colorado Springs, Colorado. Applied Flow Technology (AFT) is the premier piping and ducting systems analysis and modeling software. With an unmatched combination of capability and ease-of-use, AFT software products are used in more than fifty countries and in just about any industry in which you find piping and ducting systems. For more information, visit www.aft.com.

____________________________________________

MODERN PUMPING TODAY, March 2017

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()