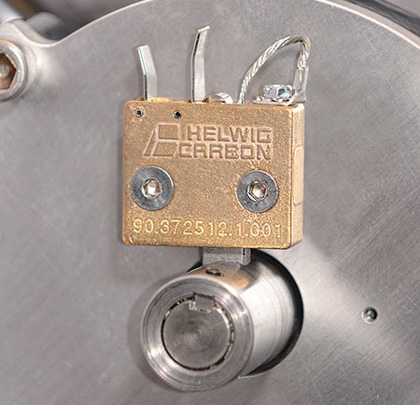

HELWIG CARBON INC.

Bearing Protector Shaft Grounding Assembly

Helwig Carbon launches a new line of shaft grounding systems to protect motors from bearing failure, a major cause of motor downtime. The Helwig Bearing Protector will give years of service while maintaining low shaft potential, minimizing your chance of having stray currents pass through the bearings. The Bearing Protector is a cost effective way to keep shaft voltage to a minimum. The stock kits fit most motors and various shaft sizes. They are easy to install, maintain, and work effectively in contaminated environments. Helwig’s grounding assemblies divert static and induced electrical currents in the motor shafts away from the bearings, protecting them from pitting and potential damage. Download a pdf file at www.helwigcarbon.com/literature.html or contact Marvin Herche by calling 414.362.6241 or emailing marvin.herche@helwigcarbon.com.

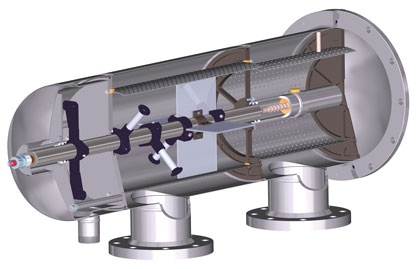

VAF FILTRATION SYSTEMS

Automatic Self-Cleaning Filters

VAF Filtration Systems specializes in the engineering and manufacture of automatic self-cleaning individual, modular and skid mounted filtration systems that include integrated controls and valves for cooling tower, pre-RO, water, waste water applications, and many more. The patented Bi-directional Hydrodynamic Drive (BHD) design does not require electric motors, limit switches, gearboxes, hydraulic pistons or any external shaft seals. The cleaning cycle of each filter takes less than 15 seconds and does not interrupt flow during the filtration process. The stainless steel filter bodies come with a 5-year body warranty against leaks. Virtually limitless flow rates and various degrees of filtration are available from 1500 to 10 micron. For filter or system application assistance from an experienced application engineers, call 303.425.4242 or email sales@vafusa.com or visit www.vafusa.com to see a demonstration of the filter’s operation.

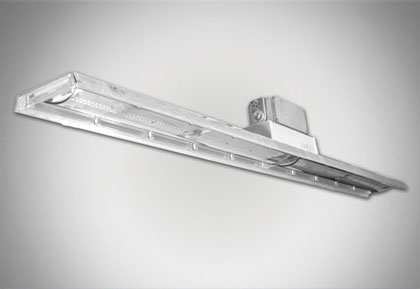

DIALIGHT

SafeSite® LED Linear Fixture

Delivering an ultra-efficient 106 lumens per Watt, the new SafeSite LED Linear fixture is available in 2-foot (33W) and 4-foot (66W) models and is less than an inch in height and 11 pounds making installation and maintenance simpler, safer, and less cumbersome. The 100-277VAC linear fixtures also feature an integrated wiring box to provide easy access for making electrical connections in a separate compartment. Dialight’s products are listed on the U.S. federal government’s GSA Schedule 56, contract number GS-07F-0664X. To get more information about Dialight’s complete line of SafeSite LED lighting solutions for hazardous locations, including IES files, LM79 reports, and technical datasheets, visit www.dialight.com.

ABB

ACQ550 Variable Frequency Drive

ABB announces the availability of its first Water and Wastewater industry-specific drive as a cornerstone product. Designed for extremely fast and easy set-up, the new ACQ550 drive now is available from 1 to 550 horsepower, and is manufactured in New Berlin, Wisconsin, for responsive production and delivery to local users in the U.S. and Canada. The drive seamlessly integrates as a NEMA1, drip-proof NEMA-12, or outdoor-rated NEMA-3R solution. It comes with a library of pre-programmed start-up assistants for commissioning submersible, centrifugal, or positive-displacement pumps, and application macros for configuring inputs, outputs, and parameters. For more information, contact Ken Graber at 262.780.3873 or ken.j.graber@us.abb.com, or visit www.abb.us/drives.

WILDEN

EZ-Install TPE Diaphragms

Wilden®, the worldwide leader in air-operated double-diaphragm (AODD) pump technology, announces that its complete line of EZ-Install TPE Diaphragms are available as a convenient and simplified replacement of traditional diaphragms. Wilden’s new EZ-Install TPE Diaphragms have been designed so that the operator in the field does not need to invert the diaphragm during the installation process. This improvement will reduce the installation time, lower maintenance costs and improve uptime. EZ-Install diaphragms are available in Santoprene®, Hytrel®, Polyurethane, and Geolast® options. Geolast is a recent addition to Wilden’s material options. It is an injection-molded material that is ideal for applications requiring enhanced oil resistance equivalent to that of nitrile (Buna-N) at a lower cost. A short video of the Wilden EZ-Install Diaphragms has been developed and can be viewed on the PSG YouTube channel: www.youtube.com/pumpsolutionsgroup and searching for “Wilden EZ-Install.”

YASKAWA

MV1000 AC Drive

The MV1000 is a medium voltage (MV) AC drive that takes a generational leap in ease of application and installation. With Yaskawa’s Smart HarmonicsTM Technology input isolation transformer and 9 level output (17 level line-to-line), the biggest traditional issues with the application of MV drives all but disappear. The MV1000, available in 2400V and 4160V versions through 5000HP, offers high performance and proven Yaskawa reliability. Based on the A1000 control platform, application flexibility is assured. Yaskawa’s proven QC/QA processes offer the highest reliability in the MV drive industry. The MV1000 is a compact, all-in-one package including (optional) input switchgear, ideal for new or retrofit installations. For more information, visit www.yaskawa.com.

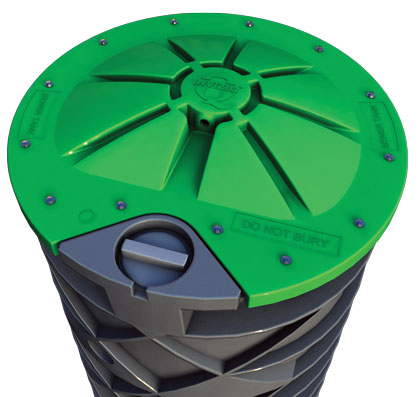

INVIZIQ

Pressure Sewer System

The InviziQ™ Pressure Sewer System is a smarter alternative to conventional gravity sewage options. Rather than relying on gravity and a network of costly lift stations to transfer sewage, PSS utilizes reliable grinding and pumping technology to efficiently and responsibly move sewage to treatment facilities—no matter the terrain, slope, environmental sensitivity of the area or complex topography of the region. InviziQ’s advanced technology and enhanced features deliver a new level performance, durability and reliability than competitive systems. InviziQ offers “Dry Well” design, the first and only PSS alternative delivering clean access to the system motor and other working parts of the unit. In addition, network monitoring and control is built into the system and its monitoring system is the most robust in the market. Whether it’s replacing an existing infrastructure or helping develop underutilized areas, InviziQ is changing the way people think about sewer systems. For more information, visit www.inviziq.com.

NIDEC MOTOR CORPORATION

U.S. Motors® Extra High Thrust Inverter Duty Vertical HOLLOSHAFT® Motor

The new Extra High Thrust Inverter Duty Vertical HOLLOSHAFT® Motor, joins Nidec’s U.S. Motors® brand family, which provides more NEMA Premium® vertical motors to the agriculture/irrigation industry than any other manufacturer in the world. In addition to meeting NEMA MG-1 Part 31 specifications, the motor offers additional features to protect against stress that the NEMA specs do not address, including:

- Insulated motor bearings that minimize bearing fluting caused by VFD induced motor shaft currents

- Motor shaft grounding rings that protect motor and pump bearings by shunting VFD-induced shaft current to ground

- Motor winding thermostats that add protection against damage caused by VFD induced overheating, critical when irrigating crops on extremely hot days

- Premium-efficient rotors with special balance and low-loss lamination steel that contribute to lower operating temperatures, in addition to reducing the cost of operation

- Space heaters that reduce condensation which can lead to motor winding failures and lubricant contamination

The new motor is currently available from stock in the 100 to 350 horsepower range. For more information, visit www.nidec-motor.com.

AUTOMATIK PLASTICS MACHINERY

PRIMO 200E

PRIMO 200E is a new single-side mounted dry-cut strand pelletizer with an extra-large cutting width of 200 millimeters. PRIMO 200 E combines a broad range of skillfully designed product features delivering user friendliness and productivity. Among single-side mounted strand pelletizers the PRIMO 200E scores highly thanks to its unique cutting geometry with the shortest unguided length between the feed rolls and the cut. This geometry enables optimum straight cutting of both hard and very soft plastic strands, all in top quality. Highlights of the PRIMO 200E are its cutting tool sets for hard, abrasive, and soft, flexible plastics. The pellet dimensions can be quickly changed by means of an optional automatic pellet length adjuster. This is done using a second drive motor for the feed mechanism with an integrated speed control. For more information, contact Ruth Ploch at ruthploch@maag.com.

GE MEASUREMENT & CONTROL

Bently Nevada Motor Stator Insulation Monitor (MSIM)

GE’s Measurement & Control business has introduced the Bently Nevada Motor Stator Insulation Monitor (MSIM) to monitor the motors that drive the world’s most critical assets. With motor stator insulation failure accounting for two-thirds of medium voltage motor failures worldwide, the MSIM detects motor insulation degradation and provides early warnings of motor failure. GE’s predictive capability helps to reduce the economic impact of motor replacement and repair by assessing the condition of the motor without taking the motor offline or shutting down the process. MSIM technology enables the continuous and industry-first direct measurement of stator winding capacitive and resistive leakage currents. MSIM relies on High Sensitivity Current Transformer (HSCT) to measure the very small leakage current in the milliamp (mA) range in the presence of hundreds of amps. In addition, the MSIM monitor uses High Voltage Sensors (HVS) with interface modules, along with motor stator temperature (RTDs or thermocouples) as inputs to the system. For more information on MSIM, visit www.ge-mcs.com/en/bently-nevada-monitoring/continuous-online-monitoring/motor-stator-insulation-monitor.html.

SULZER PUMPS

ABS Submersible Sewage Pump XFP

Designed for use in engineered pumping stations, the ABS submersible sewage pumps XFP models PE4 to PE6 are part of Sulzer Pumps’ ABS EffeX range. With the premium-efficiency IE3 motor, the ABS submersible sewage pump XFP sets a new standard for the wastewater industry. Yet the motor is only one of its many remarkable characteristics. The pump is a complete, highly engineered package whose design takes into account all aspects of wastewater handling.

Key advantages of the ABS submersible sewage pump XFP include:

- Greater energy savings with a lower operating cost and reduced carbon footprint as a result

- Long-term reliability reduces not only energy costs and maintenance, but also the risk of overflows and breakdowns

- Excellent rag handling with the new Contrablock Plus impeller

- Future-proof design exceeds existing and planned worldwide legislation regarding equipment efficiency

- Sustainability in manufacturing and operation

For more information, visit www.sulzer.com or www.abseffex.com.

ALMATEC

E80 AODD Pump

Almatec®, a premier manufacturer of air operated double-diaphragm (AODD) pumps specializing in plastic pumps with solid housings, launches the E80 model in its family of E-Series AODD Pumps. The E80 is currently the largest model in the E-Series family of solid-body plastic AODD pumps from Almatec. Like all E-Series pumps, the E80 is made in solid construction, and has dry-run and self-priming capabilities. They also have no rotating parts and no shaft seals for improved performance and lower maintenance. The massive plastic body of the E80 meets the required mass for an oscillating working pump and the necessary security requirements for different conveying tasks. The E80 is constructed with abrasion-resistant polyethylene, and is ideal for use in abrasive and difficult-to-handle applications. The E80 is designed with integrated flanged connections to ensure high stability and leakage protection. For more on Almatec pumps, visit www.almatec.de.

MOYNO, INC.

Sealless Mag Drive Pumps

Moyno™ Mag Drive pumps are the first progressing cavity wobble stator pumps to offer magnetic drives. The patented sealless, magnetic drive design provides zero leakage for the most critical applications. These pumps can handle toxic, aggressive, caustic or even flammable and explosive fluids. This proprietary progressing cavity mag drive pump utilizes the latest technology to ensure operator safety, eliminate work place hazard and protect the environment from contamination. Typical applications include sodium hypochlorite, ammonia, hydrogen peroxide, ferric chloride, aluminum chloride, and many other caustic fluids. For more information, call 877.4UMOYNO or visit www.moyno.com.

_________________________________________________________________________

MODERN PUMPING TODAY, December 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()