In the first part of this series, we examined some of the benefits of reusing wastewater, especially as it relates to food and beverage processing, as well as guidelines for identifying the right treatment options for a specific need. We’ll continue that focus in this installment. When a facility is looking to apply an advanced treatment process, they can be broken down into two categories: biological and disinfection.

BIOLOGICAL TREATMENT

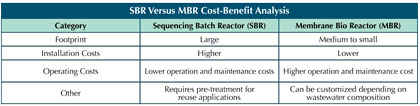

Under biological treatment there are two subcategories: Sequencing Batch Reactor (SBR) and Membrane Bio Reactor (MBR). Generally, SBR will have lower capital requirements than MBR, but MBR systems will cost less to operate. They combine biological treatment with membrane filtration to provide a high quality effluent, meet stringent nutrient limits for phosphorus and nitrogen, and have a smaller footprint compared to SBR technology. For a more detailed comparison of SBR to MBR, refer to Table 2.

Table 2: SBR versus MBR cost-benefit analysis

DISINFECTION

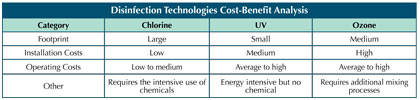

Under disinfection treatment there are three categories: chlorine, ultraviolet (UV), and ozone. The most basic form is chlorine disinfection. In this treatment type, water is filtered with hypochlorite to generate chlorine residual that inactivates pathogens such as bacteria.

UV technologies are chemical-free and require less contact time than chlorine disinfection. In these systems, water is channeled through a reactor that emits UV light at low wavelengths to destroy the DNA structures of microorganisms, including bacteria, viruses, yeasts and molds. Virtually any liquid can be used with this technology, so it is often found in beverage-processing plants; however, UV is sensitive to the clarity of the water. Higher clarity water requires less energy to treat, and, as a result, pretreatment of wastewater is common in systems where UV disinfection is used.

Ozone and Advanced Oxidation Processes (AOP) are powerful oxidation treatment technologies that generate hydroxyl radicals, the strongest oxidant used in water treatment. AOP is an ideal disinfection approach to treat recalcitrant contaminants that are otherwise not removed by other technologies. AOP and ozone technologies are commonly coupled with other filtration technologies. Table 3 outlines a cost-benefit analysis of common disinfection technologies.

Table 3: Disinfection technologies cost-benefit analysis

In addition to the biological and disinfection techniques presented above, there are other advanced treatment technologies that can be used either separately or in conjunction to fulfill wastewater discharge requirements.

MEMBRANES

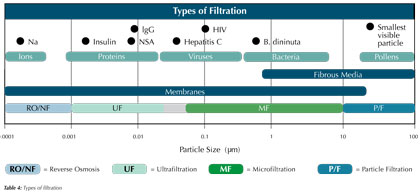

Membrane filtration, using technologies such as microfiltration and ultrafiltration, provides suspended solids removal found in the processing of foods and beverages. These technologies can remove some pathogens, viruses and bacteria. See Table 4 for a breakdown of filtration types.

REVERSE OSMOSIS (RO)

In reverse osmosis, salts and many dissolved organics are removed through a semi-permeable membrane. RO is used when the highest quality reuse water is needed, such as high-pressure boiler feedwater or any use where low salt and contaminant levels are required. RO can be expensive and generate a concentrated brine waste stream that must be managed via proper disposal.

A LOOK AHEAD: PUMPING SYSTEMS

Treating water is only the first step to ensuring wastewater is recycled and reused efficiently and effectively within a plant. It is important for organizations to also consider the transportation and storage of water reuse. Pumps serve two purposes in a reuse system: transporting and pressure boosting. In the conclusion to this series, we’ll address the keys for selecting the right pump, implementing a water reuse system, and ensuring standards for sustainability and safety. ■

REFERENCES

1. Shiklomanov, Igor. “World Fresh Water Resources.” Water in Crisis: A Guide to the World’s Fresh Water Resources.Ed. Peter H. Gleick. 1993. Print.

2. The Water Resources Group. Background, Impact and the Way Forward. Rep. 26 Jan. 2012. 16. Web.

3. EMD Millipore. “Filtration Basics.” Millipore Membranes and Filtration. Web.

4. United States. Environmental Protection Agency. 2012 Guidelines for Water Reuse. Sept. 2012. Web.

5. The Coca-Cola Company. 2012/2013 GRI Report “Water Stewardship.” Rep. Web.

About the Author

Nate Maguire is the Americas business unit director, industry, and agriculture for Xylem’s applied water systems business unit; Greg Claffey is Xylem’s director of treatment sales, North America; and Keel Robinson is Xylem’s North America reuse marketing and business development manager. Xylem’s well-known global brands provide world-class products, comprehensive solutions, and unmatched applications expertise in more than 150 countries. To implement a water reuse system in your facility, visit www.xyleminc.com/food.

MODERN PUMPING TODAY, September 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!