Part 4 in a 4-Part Series

Like any business decision, choosing the right air-operated double diaphragm pump (AODDP) for your application requires careful consideration. You wouldn’t hire a new plant manager without verifying the candidate’s experience. The same goes for AODDPs. Performing due diligence is critical. Whether you need one pump or a thousand pumps, you deserve the best fit and performance for your investment. You should research, ask pointed questions, and expect honest, evidence-based answers.

In this final installment of our four-part series, we’re going to look at the three important questions you should ask pump manufacturers to make sure you get the pump that provides the best mix of performance, efficiency and value for your needs.

FIRST THINGS FIRST

For those of you joining our ongoing series for the first time (and for those of us who devote the bulk of our memories to things like website passwords and anniversary dates), here’s a quick look back at what we covered in the previous three articles.

We started out covering the AODDP basics: how they work, how to read performance curves and how to calculate pump operating costs. Then, we moved into an overview of all the ways that All-Flo’s A200 revolutionized AODDP technology, performance and efficiency (by reducing and optimizing dead space on the liquid and air sides of the diaphragms and improving main air valve timing). After that, we talked about how to compare and contrast pump performance across the industry by using data-driven evaluations to help you cut energy costs and improve ROI.

Now, that we’re all caught up, let’s get the AODDP manufacturer inquisition underway!

GRADE ON A CURVE

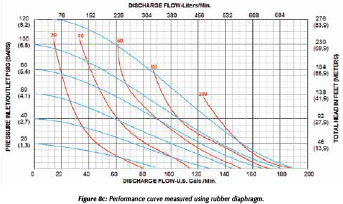

If the most efficient, cheapest pump on the market doesn’t reliably do the job you ask it to do, what’s the point? At the end of the day, performance is king. In our industry, performance curves are essential tools for determining and evaluating performance. Any reputable pump manufacturer should be able to produce accurate performance curves for you to review.

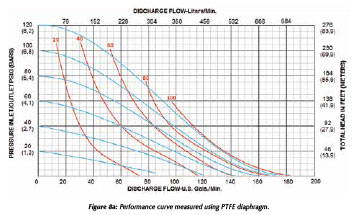

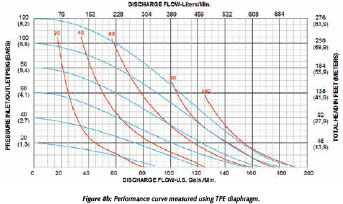

Furthermore, they should have curves that document the performance of pumps with diaphragms made from the materials you’re interested in (most commonly PTFE, rubber and thermoplastics).

Figure 8a Performance curve measured using PTFE diaphragm.

The ability to compare pumps with diaphragms made from different materials is critical because those diaphragms can impact overall performance, air consumption and key factors such as dry suction lift. This difference is evident in the All-Flo A200 performance curves included in the figure 8 graphs. These performance curves all belong to 2-inch AODDPs that are identical in every way except diaphragm materials. As you can plainly see, the air consumption and performance vary from pump to pump, with PTFE diaphragms claiming the most dramatic difference. Pump performance directly impacts efficiency, which, in turn, directly impacts operating costs and ROI.

Figure 8b Performance curve measured using TPE diaphragm.

Of course, performance curves alone probably won’t dictate your selection. Some materials are just better suited for certain applications than others, no matter what the curve says (think caustic liquids versus water, and so on). That being said, you are entitled to all the data required to make an informed decision.

DIG A LITTLE DEEPER

A big part of an AODDP manufacturer’s job is to make sure that its pumps deliver the performance it promises. To do this, companies such as All-Flo develop rigid internal testing protocols that are used to test pumps, re-test them, and then test them some more. After each evaluation, pump components are checked for quality and reliability, setups are tweaked if necessary, and overall performance is fine tuned. Data from the tests are used to generate performance curves. These protocols are extremely important to us, as manufacturers, because we know that, at the end of the day, if our AODDPs don’t work like they say they will, you will buy them from someone else. (We place a great deal of value on our reputations and customer satisfaction.) These protocols are important for you, as a user, because they ensure quality and accountability.

Figure 8c Performance curve measured using rubber diaphragm.

When you ask a manufacturer to share its testing protocol, what you’re really asking is, “How did you get the information I see in your performance curves?” Because we put so much time and effort into creating and executing our protocols, they become sources of pride that we are happy to share with interested customers. Nothing builds trust like transparency, and we always want you to feel good about your choice.

KICK THE TIRES, SO TO SPEAK

In some ways, buying a new AODDP is a lot like buying a new car. You listen for the sweet sound of the engine’s hum, catch a whiff of that exhilarating “new pump smell”—OK, maybe not. However, just as the test drive is an integral part of the car-buying process, a figurative test drive can be just as useful for AODDP purchases. Before you sign on the dotted line, your manufacturer should allow you to see how the pump you’re considering will perform in your reality; to kick the tires and take it for a spin.

Field testing will help you evaluate a pump’s true performance and efficiency. You can even set up multiple tests to pit one manufacturer’s AODDP against another’s. In lieu of field testing, if a manufacturer stands behind its published efficiency claims, it should have no problem allowing you to supply equipment such as air consumption meters to verify its data. Supplying your own equipment will guarantee that you get a fair and accurate reading that you can trust.

WRAPPING UP

In your business, AODDPs probably don’t share the spotlight with big-ticket purchase items such as new oil rigs or the million-dollar machines that corporate marketing folks like to point out on factory tours. But because choosing the wrong pumps for your needs can cost you hundreds of thousands of dollars a year in unnecessary operating expenses and unscheduled downtime, it’s worth your time to make careful, well-informed decisions. Always perform your due diligence, hold pump manufacturers accountable, and remember that the value of a well-designed AODDP extends well beyond its initial purchase price.

ABOUT THE AUTHOR

Paul McGarry is the All-Flo sales and marketing manager for North America. To learn more, visit www.all-flo.com, and www.aoddpumpefficiency.com.

MODERN PUMPING TODAY, July 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!