Recent changes in solar pumping technology have the potential to turn the market on its head. For years, solar-powered pumping systems have been used as an option in remote locations, in applications with unreliable power, and for occasional special requests. Their use has often been limited by low flow pumping options that cannot generate enough water before they run out of daylight. The SubDrive SolarPAK from Franklin Electric stands to change all that.

THE NEW LOOK OF SOLAR POWER

Two things make Franklin’s solar pumping system different from others already on the market: its simplicity and its output volume. Designed to use a standard submersible pump and motor combination, no special equipment or training is required. Installers of the SolarPAK can continue to do what they do best: function as pump experts rather than having to become solar experts.

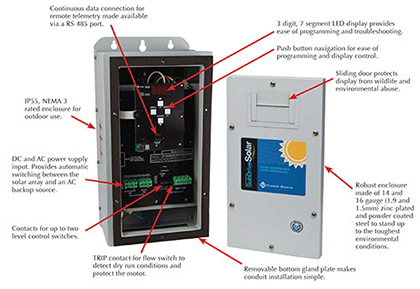

The workhorse of the system is the solar-powered controller. The unit comes ready-to-go and wires just like a standard control box: power in, power out. Built-in functionality includes the ability to control tank water levels, pressure systems, timers, relays, or irrigation zones. Fault protection and remote communication are also standard in every controller. The customer needs only to choose the features he wants to use.

POWER TO SPARE

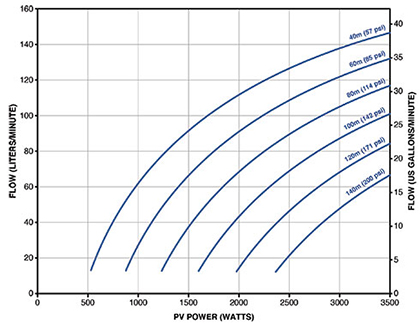

For its simplicity, the SubDrive SolarPAK can move a lot of water. Where other manufacturers’ systems often utilize progressive cavity pumps that typically pump at much lower flow rates, Franklin Electric’s system uses a proven submersible centrifugal pump design that can move higher volumes of water quickly. With flow ratings up to 90 gallons (340.7 liters) per minute, this means that the system requires fewer hours of sunlight per gallon pumped. Because the system can deliver enough water to fully meet the application’s demand in a shorter period of time, the customer can allow the solar array to provide electricity for other purposes. When the water system again calls for the pump to run, the SolarPAK will automatically switch back to normal pump operation with no manual input.

SUBDRIVE SOLARPAK

The SubDrive SolarPAK is a complete, one-box, system solution that provides the pump components needed to build a solar powered water well system. Designed specifically for pumping clean water using a renewable energy supply, SubDrive SolarPAK includes a solar-powered controller, a submersible pump and motor, and a flow switch. Using a solar PV array as the input power source, SubDrive SolarPAK is ideal for use in applications where traditional grid power is unavailable, unreliable, or undesirable.

The release of SubDrive SolarPAK follows an intense development process based on voice of customer research and proven design principles, as well as more than a year of testing and operation in global markets. The system has demonstrated itself to be robust and reliable in a wide variety of weather and application conditions.

NEW PLACES TO SHINE

Because of SolarPAK’s operational advantages, customers are already finding new ways to apply the technology. A coal mine in Texas, for example, has engineered a system that uses two SolarPAK systems mounted to a portable skid of solar panels. The skid can be moved around as needed to irrigate trees which are planted on land being reclaimed after the coal mining operation has been completed. One of the systems pumps water from a well to two holding tanks, while the other pumps water from the tanks to into a pressurized irrigation system. Solar energy gives it the mobility and versatility to be used anywhere on the site.

Another user has introduced the SolarPAK to irrigate roads in order to minimize dust. In the past, water trucks have been used to serve this application, but those trucks require fuel and release unwanted emissions into the atmosphere. The SolarPAK offers a clean, environmentally friendly alternative that can be installed anywhere there is a viable source of groundwater.

FIND THE RIGHT MATCH

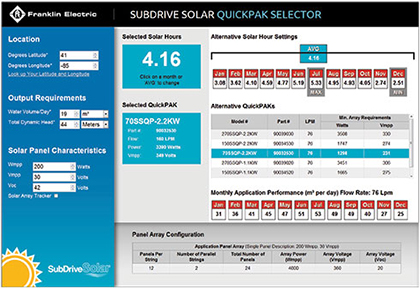

In addition to the product itself, Franklin Electric has made system-specific support software available on a solar-dedicated website. The Solar Selector allows users to input simple location information and water requirements to determine which SubDrive SolarPAK fits the application. The Solar Selector also provides recommendations for panel array configuration based on user-entered panel characteristics.

There are three things pump users would need to specify on this page in order to properly size a solar pumping system:

- Where is the installation located? (This will help determine how much sun is available.)

- How much water is needed in terms of pressure and volume? (Just like a conventional system.)

- What are the electrical characteristics of my solar panels?

With this information, the system calculates how much sun should be available based on the latitude and longitude of the installation. Chances are, you don’t have those numbers handy, but that’s not a problem. Although you can enter the latitude and longitude of the installation directly, an easier way is to select “Look up Your Latitude and Longitude” using the crosshair tools and the SolarPak Selector will do the rest.

It is just as simple to specify how much water you need per day and at what total dynamic head. Note that the volume requirement per day can be expressed in cubic meters (m3), gallons, or liters. The drop down box allows you to select your unit of measure. Similarly, total dynamic head can be expressed in meters, feet, or PSI, again specified with the adjacent drop down box. Once you enter this information, the SolarPak Selector goes to work and provides a wealth of information, including which Franklin system is recommended for this installation.

Lastly comes finding the right solar panel. After all, it’s the panel that captures the sunlight needed to run the system. Several different variables are associated with solar panels, but for a pumping system, we only need to consider four values: Voc, Vmpp, Impp, and Wmpp. Voc stands for open circuit voltage and is exactly what the name implies. That is, with no load (zero current being delivered), the array will generate this amount of DC voltage. This is similar to measuring AC voltage from the power company in a conventional water system when the motor is not running. The point where the most power is delivered is denoted by Wmpp, or maximum power point watts. It’s also sometimes called just Pmax or maximum power. The voltage and current at this point are called Vmpp and Impp for maximum power point voltage and maximum power point current, respectively.

STEPPING INTO THE SPOTLIGHT

Requests have come from all over the world for Franklin Electric’s SubDrive SolarPAK in water pumping applications not typically associated with solar energy. From installations currently on the grid to generator-powered sites to completely new concepts, SolarPAK offers opportunities anywhere four-inch submersible pumps are used.

_______________________________________________________________________

ABOUT THE AUTHORS

Tammy Davis is the director of corporate communications and Mark Reeder is the director of field marketing for Franklin Electric, a global leader in the production and marketing of systems and components for the movement of water and automotive fuels, serving customers in residential, commercial, agricultural, industrial, municipal, and fueling applications. For more information, visit www.franklin-electric.com/solar.

_______________________________________________________________________

MODERN PUMPING TODAY, June 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!