Move from search to solution quicker and more successfully

A search on Google for “sensors” delivers 38,600,000 results. Even the more specific search for “liquid level sensors” dumps 4,520,000 results in your lap. Whether you call it information overload or the “Tyranny of Choice,” it adds up to a daunting task as an engineer to source the ideal sensor component for a particular application.

A search on Google for “sensors” delivers 38,600,000 results. Even the more specific search for “liquid level sensors” dumps 4,520,000 results in your lap. Whether you call it information overload or the “Tyranny of Choice,” it adds up to a daunting task as an engineer to source the ideal sensor component for a particular application.

One way to simplify the search is to start with a company that has application expertise and the willingness to share it, combined with a broad portfolio of sensor product types and technologies. A conversation with a sensor application specialist can rapidly introduce the options available for a given project and, more importantly, provide clarity on the pros and cons of a specific sensor in the context of your application.

Taking this route can save time over the hit and miss results of typical internet searches. A frictionless translation of “engineering needs” to “sensor solution” is the goal of any time-constrained engineering project.

EMBRACE TECHNOLOGY ALTERNATIVES

A typical aggravation for a sourcing engineer is the single-technology manufacturer. For instance, if you consult with a company that makes only ultrasonic sensors, they will most likely recommend an ultrasonic sensor for your application, even though there may be alternatives that can do the job better in a variety of ways—size, price, accuracy, etc. It’s natural for them to recommend the technology they are most familiar with, and of course they want to sell their product. But it is not necessarily the best fit for your product or company’s success.

As an engineer it is beneficial to devote precious time resources to a source that can evaluate the pluses and minuses of multiple technology paths, in order to deliver the best possible solution. Plus there is a level of confidence afforded when a recommendation is made by a company without a vested interest in one particular technology. Beware of those pounding round pegs into square holes.

FIND A VENDOR WHO PROVIDES CHOICE

FIND A VENDOR WHO PROVIDES CHOICE

Selecting a sensor, even from a reputable source, is never easy if choices are slim. Easing your task of finding the right sensor will be expedited by starting with a source that can show you the pros and cons of different technology options as they apply to your application.

Many engineers like to begin with a company’s website, and that can be a good way to familiarize yourself with the options they offer. With a broad range of fluid sensing technologies and lots of information to download on each product, however, it can quickly become overwhelming. That’s when it’s time to get in touch with someone who can point you in the right direction, whether you prefer to submit a contact form or pick up the phone.

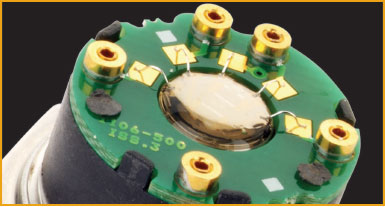

For example, within each of Gems’ primary sensing categories—level, flow, and pressure—there are dozens of product series and hundreds of unique sensors. A Gems representative can make the difference in pinpointing the specific sensors and customizations that make sense for a particular application.

KNOW MANUFACTURING CAPABILITIES

KNOW MANUFACTURING CAPABILITIES

Knowing about a potential sensor vendor’s manufacturing credentials can avoid the quality control and fulfillment problems that can cause disasters downstream. Sensor malfunctions can damage expensive equipment when coolant runs dry, or lead to hazardous spills if a high level alarm fails. Selecting from a source with the right certifications and internal process controls goes a long way to ensure that your sensor choice will be the reliable one.

PRIORITIZE A GLOBAL REACH

Understanding how and where the sensor will be used in various applications is an important consideration. Is the sensor being sourced going into a product that will be deployed internationally? Do the components need electrical safety certifications from multiple agencies? Will attributes such as port thread types or electrical termination vary depending on the country into which it will be sold? Will your product be manufactured in various plants around the world?

If the answer to any of these questions is “yes,” you should narrow your sensor selection search to companies that have global capabilities and reach.

TAKING A BROAD APPROACH

With these above considerations in mind, Gems Sensors & Controls takes a broader approach to sensor technology, designing and manufacturing sensors around a wide range of the most effective technologies, with the recognition that each has strengths and limitations. Gems holds stringent ISO 9001 and ISO 13485 quality registrations, and additionally implements strict design controls and management processes throughout all aspects of its business. These include

- Design control and documentation

- Risk management

- Process yield / defect analysis

- Statistical process control (SPC)

- Formal corrective / preventive action

- Training and certification programs

- Material traceability systems

- And, as necessary, sensors from Gems carry important agency approvals including CSA or UL-recognition and CE Marking.

KEEP IT SIMPLE

KEEP IT SIMPLE

With representatives, distributors and customer service around the globe, Gems speaks your language, too. This global reach simplifies logistics and after sales service. Although it may not specifically change the process by which you select a sensor, it certainly impacts with whom you should select a sensor.

Simplifying the search for the perfect fluid sensor has been a sixty-year mission at Gems Sensors & Controls. By keeping the end-user’s selection process at the forefront of design and manufacture, Gems is the easiest and most successful path to a solution, an ideal starting point of your next sensor search.

■ ■ ■

[divider]

FOR MORE INFORMATION

Gems Sensors & Control is a leading global manufacturer of liquid level, flow, and pressure sensors; solid-state relays and barriers; liquid and pneumatic miniature solenoid valves; and pre-assembled fluidic systems with facilities in North America, Europe, and Asia. For more information, call 800.378.1600 or visit www.gemssensors.com.

MODERN PUMPING TODAY, March 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!