Lubrication is the lifeblood of industrial machinery. Whether it is pumps, motors, or other high-end equipment, the demands of constant use common in industrial applications require reliable solutions for staving off machine seizures due to lubrication failure. Colfax Fluid Handling, a global leader in fluid handling solutions for critical applications, has launched the new 2BIC series of pumps for low-pressure lubrication of rotating machinery and other equipment and its CFHN series for medium-pressure applications.

Both pumps were created in response to real-world concerns over the perceived limits of forced oil flow, and the experts at Colfax Fluid Handling believe they have provided a solution that will extend the service life across a range of industries. However, manufacturers who choose either of these pump series to best fit their needs will be happy to hear what they won’t hear. The 2BIC and the CFHN series were designed with the modern industrial plant in mind and operate as quietly as they do reliably.

2BIC: A LOW PRESSURE SOLUTION

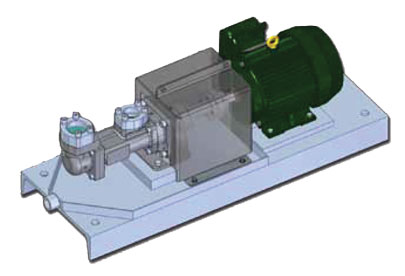

The 2BIC series provides a compact solution for low-pressure lubrication of rotating machinery and other equipment where forced oil flow is required. Based on Colfax Fluid Handling’s proven three-screw design, the 2BIC series delivers the benefits that matter most to original equipment manufacturers (OEMs) for low-pressure lubrication applications: quiet operation, long service life, and low pulsation to provide the highest “Total Savings of Ownership” across the life-cycle of equipment.

Featuring a close-coupled design, the 2BIC eliminates the need for a coupling or lantern bracket to attach the motor, reducing overall length of the pump-motor assembly by up to 10 inches (254 millimeters). The ISO interface points, which can be rotated in 90 degree increments, along with a flange mount suitable for connection to IEC B5 motors, make the 2BIC a truly global design. Available in six displacements across three frame sizes, the 2BIC close-coupled pump is capable of pressures up to 175 psig (12 bar) and flows up to 70 gallons (265 liters) per minute.

The 2BIC Series’ robust industrial design ensures years of trouble-free service. Maintenance and replacement are virtually eliminated by locating the ball bearing within the pumped liquid to provide constant lubrication and cooling. Elastomeric components are made of durable fluorocarbon, and the case and covers are constructed of aluminum (or a cast iron inlet head on one model, the 2BIC-95). The 2BIC is also fitted with a spring-backed lip seal.

CFHN: FOR MEDIUM PRESSURE

For OEMs of rotating machinery who desire a solution using Colfax’s three-screw design but need to pump clean lubrication oils at medium pressure, the CFHN series provides the same quiet operation, long service life, and low pulsation as the 2BIC. This makes the CFHN a versatile solution that still delivers the highest “Total Savings of Ownership” across the equipment’s life cycle.

Configurations include an ISO foot or flange mount and ISO interface points that, like the 2BIC series, can be rotated in 90 degree increment, making the CFHN series suitable for nearly any mounting and piping configuration. Available in seventeen displacements across six frame sizes, the CFHN pump is capable of greater pressures—up to 580 psig (40 bar)—and flows—up to 200 gallons (760 liters) per minute—than its 2BIC counterpart.

The CFHN series offers a heavy-duty design for years of trouble-free service. The ball bearing is located within the pumped liquid to provide constant lubrication and cooling, virtually eliminating any required maintenance or replacement. Elastomeric components are made of long-lasting fluorocarbon, and the case and covers are constructed of cast iron for enhanced thermal properties. The CFHN is also fitted with a friction drive and a single spring mechanical seal.

SOMEWHERE MORE QUIET

With a broad portfolio of technologies, products, systems, and services and a deep base of application and engineering expertise, Colfax Fluid Handling specialists have worked with customers to understand and focus on their toughest challenges. As a result, Colfax Fluid Handling can find and deliver the best customer solutions that provide the highest levels of reliability, efficiency, and longevity with the lowest total cost of ownership. Whether a manufacturer needs delivery of low-pressure or medium-pressure lubrication, the Colfax Fluid Handling series of pumps is made for the job—even if they can’t be heard doing it.

_______________________________________________________________________

ABOUT THE AUTHOR

Jim L. Davis is the three screw pump and internal gear product specialist for Colfax Fluid Handling with over thirty years practical experience in the pumping application industry. Colfax Corporation, a diversified global manufacturing and engineering company, provides gas- and fluid-handling and fabrication technology products and services under the Howden, Colfax Fluid Handling, and ESAB brands. He can be reached at jim.davis@colfaxcorp.com or 704.289.6511, ext. 102390. Additional information about Colfax is available at

www.colfaxcorp.com.

_______________________________________________________________________

MODERN PUMPING TODAY, August 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!