The market for liquefied natural gas, or LNG, is on the rise. And with the increase in demand comes a correlating increase in innovation. Dresser-Rand recently designed, constructed, and commissioned its first small-scale liquefied natural gas plant, a demonstration plant that has reached a key milestone with the initial production of LNG. Extended performance and endurance testing is underway. Dresser-Rand is already stocking plants that are ready to ship today.

EXCITEMENT OVER LNG

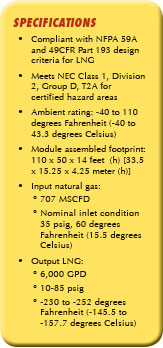

“We are very excited about this technology for small-scale LNG production, which allows for very small stand-alone plants that are portable and can be moved to support changing requirements and needs,” says Dresser-Rand president and chief executive officer Vincent R. Volpe, Jr. “The standard LNGoTM plants are sized to produce approximately 6000 gallons [22,712.5 liters] of LNG per day. There is substantial Dresser-Rand scope potential in this offering including our newly introduced MOSTM reciprocating compressor, Guascor® engines, Enginuity® control systems, and project management to integrate all of these and the process components into compact, portable packages.

“Our development process began in earnest less than one year ago,” says Volpe. “In this timeframe, our organization has taken the process and designed, built, and commissioned an entire plant. This development cycle time to market is amazingly short, and is a tribute to our internal processes, as well as to the men and women of our development team, and our Painted Post Operations.”

PRODUCTION OPTIONS FOR SALE OR LEASE

Building on interest of over ninety qualified leads, Dresser-Rand has been talking to potential clients for several months for commercial operation. Depending upon the nature of the application, these leads are broadly classified as plants that would either be for sale or for lease.

In the “for sale” category, Dresser-Rand would provide the liquefaction process and, depending upon the plant configuration, potentially also include the associated ancillary gas processing equipment, a power module and full turn-key installation and commissioning. In the “rental” or “lease” space, the Dresser-Rand is evaluating several options, including potential market channel partners, and expects that, over the coming weeks, it will determine which approach is expected to be the most needed by the market.

FULL TURN-KEY INSTALLATION

For all users, Dresser-Rand can provide full turn-key installation and commissioning services, as well as routine operations, monitoring, and maintenance contracts, to ensure ongoing reliable and available operations.

“Now that we have produced LNG with our demonstration plant, we are in the enviable position of imminent market launch,” Volpe adds. “Given the short cycle times that we embedded into our production plans, we believe that anticipated orders booked in the next several months will convert to shipments in 2014. As those units are placed into service and gain operating experience and run time, we believe that the incoming stream of orders will then progressively grow over time.”

UPSTREAM APPLICATIONS

Upstream applications include, among others, the monetization of flared gas to increase revenues for oil companies and reduce their environmental impact, the production of stranded natural gas fields, which are not close to existing pipeline infrastructure, on-site fuel supply for drilling and hydraulic fracturing equipment converted to run on LNG, and applications for coal bed methane for fueling mining vehicles. Downstream applications include the production of vehicle-grade LNG, allowing LNG to compete effectively with diesel fuel on a cost-per-energy-content (BTU) basis.

CUTTING TRANSPORTATION COSTS

As LNGo plants enable the “distributed” production of LNG on a small-scale, the technology eliminates the need for the costly trucking of LNG long distances from large, centralized plants to LNG fueling depots, as is the practice today. Further, Dresser-Rand believes that its approach to short cycle time will enable LNGoTM plants to be installed and operating in months rather than years. The short cycle times will allow owners to see quick returns on their investment, as well as matching the supply and demand of LNG as local markets develop.

A MARKET ON THE RISE

Driven by rapidly expanding global shale gas development and continued price differentials between natural gas and oil, Dresser-Rand predicts that the market for distributed, small-scale LNG production plants will grow from early adopters in North America to a broad, robust market for users around the world. North America is the most rapidly growing market and the substantial price disparity between diesel fuel and low priced natural gas has oil-field service operators, oil and gas companies, shipping and delivery companies, and downstream fuel distributors/marketers across the region converting drilling rigs, industrial mining equipment, transportation fleets and retail fueling stations along the United States interstate highway system to LNG fuel. ■

_________________________________________________________________________

ABOUT THE AUTHOR

Charles Ely is the general manager of distributed LNG solutions at Dresser-Rand, among the largest suppliers of rotating equipment solutions to the worldwide oil, gas, petrochemical, and process industries. For more information, visit www.lng.dresser-rand.com or call 800.372.2608.

_________________________________________________________________________

MODERN PUMPING TODAY, January 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()